How Dirty Air Filters Impact Engine Performance

Reduced Airflow and Combustion Efficiency

Air filters play a really important role in keeping the right amount of air flowing into engines. When these filters get dirty, they block airflow significantly, meaning less air gets into the engine which messes with how well it burns fuel. Good combustion depends on getting just the right mix of air and fuel, so when this balance goes off track, the whole engine suffers in terms of performance. Research from various car manufacturers shows something interesting too: if the air filter is clogged up bad enough, engine efficiency can drop around 10 percent. That's why regular maintenance matters so much for air filters. Keeping them clean ensures engines get what they need to burn fuel properly, which means better performance overall and also helps save on gas money at the pump.

Effects on Acceleration and Power Output

When an air filter gets clogged, it really affects how well a car accelerates and produces power. The problem comes from restricted airflow, so less oxygen gets into the engine where it's needed for proper combustion during acceleration. Horsepower numbers tend to drop off pretty明显 when this happens. Some mechanics actually say that a dirty air filter can knock down horsepower by around 11%, give or take. Drivers will notice the difference right away since the car just doesn't pick up speed as quickly anymore. Regular maintenance matters here though. Cleaning or replacing the air filter at least once every few months keeps the engine breathing properly, maintains good power delivery, and makes driving feel better overall without compromising safety on the road.

Increased Engine Strain in Stop-and-Go Traffic

City driving means engines are constantly going from sitting still to sudden bursts of speed. When the air filter gets clogged, things get even worse for the engine in this stop-start traffic situation because less air gets through. Less airflow puts extra pressure on the engine components, making them work overtime. Research indicates engines tend to break down faster under these conditions when they don't receive proper ventilation. What happens? The engine ends up working way harder than necessary, risking overheating problems down the road. Regular checks and replacements of air filters matter quite a bit for anyone spending lots of time stuck in city traffic. Keeping that filter clean helps protect against premature wear and keeps the vehicle running smoothly over many miles.

Key Symptoms of a Clogged Air Filter

Check Engine Light Activation

When an air filter gets clogged, one telltale sign is when that pesky check engine light (CEL) starts glowing on the dashboard. What this means basically is the engine just isn't breathing properly anymore because it's not getting enough air through the filter. If folks notice this happening, they really should get their car checked out by someone who knows what they're doing. Mechanics will run some tests to see if the air filter is indeed the culprit behind all this trouble. The OBD system usually throws up codes like P0171 or P0174 when there are airflow problems connected to dirty filters, pointing toward what's called a lean air-to-fuel mixture situation. And let me tell you, ignoring those lights and codes isn't wise at all since letting things go unchecked could result in serious damage to the engine components over time.

Unusual Engine Noises and Vibrations

A dirty air filter restricting airflow can actually result in strange engine noises along with annoying vibrations throughout the car. Engines need proper air intake to run smoothly, so when they cant get enough air, drivers often notice things like backfiring from the exhaust, metallic knocking sounds coming from under the hood, or even sputtering as the car moves forward. These odd noises definitely point to trouble brewing inside the engine compartment and typically come paired with shaking sensations felt through the steering wheel and floorboards. Keeping up with routine maintenance checks helps catch these problems early on before they escalate into bigger repairs down the road. Mechanics recommend paying attention to any unusual sounds while driving since catching air filter issues sooner rather than later keeps engines running cleaner and quieter overall.

Black Exhaust Smoke Explained

When an air filter gets clogged, one thing that often happens is black smoke coming out of the exhaust pipe. The reason for this? Not enough air getting into the engine causes the fuel to burn improperly. Without sufficient oxygen, the fuel doesn't combust completely, resulting in all that dark smoke we see - basically a red flag that something's wrong with how the engine is running. Mechanics know from experience that vehicles emitting too much smoke aren't just performing poorly, they're also putting more pollutants into the atmosphere than they should. Getting those filters cleaned or replaced on time makes a big difference though. Clean air filters allow better combustion, cut down on smoke output, and keep engines running healthier over time. Most drivers wouldn't think about it until problems start showing up, but regular maintenance here pays off in both performance and environmental impact.

Fuel Efficiency Consequences

Oxygen-Starved Combustion and Gas Mileage

When there's not enough oxygen during combustion, cars just don't run as efficiently on gas. Air filters get dirty over time and start blocking airflow into the engine. Without proper oxygen levels, engines have to work harder and burn more fuel to keep going at the same speed. The result? Lower miles per gallon overall. Some tests show that really grimy air filters can actually cut fuel efficiency down by around 10 percent. That means drivers end up spending extra money at the pump when they could be saving if their filters were kept clean and working properly.

Fuel Trim Adjustments in Modern Engines

Today's car engines have built-in systems that tweak fuel delivery when airflow gets blocked by dirty filters. The engine basically tries to compensate for less air by burning more fuel just to keep things running smoothly. But here's the catch - trying to maintain both good gas mileage and decent power at the same time usually means guzzling extra fuel. Mechanics we talked to say drivers constantly struggle with this choice between getting that instant acceleration versus saving money at the pump over time. That's why keeping those air filters clean isn't just about passing emissions tests anymore. A simple filter change can actually make a real difference in both wallet size and vehicle performance down the road.

Long-Term Costs of Poor Airflow

When air filters get clogged, the poor airflow they cause can really hurt your wallet in the long run. Think about it this way: dirty filters mean more money spent on repairs down the road. Keeping those filters clean is actually one of the simplest ways to avoid big repair bills because it keeps the airflow going where it should be and maintains good engine performance. Some folks have found out the hard way that skipping regular filter checks ends up costing them way more cash than just doing the maintenance properly from the start. Taking care of air filters helps reduce strain on engines over time, which means fewer breakdowns later on and generally makes vehicles last longer before needing major work.

Long-Term Engine Damage Risks

Premature Wear on Cylinder Walls

When air filters get clogged, they restrict airflow into the engine, and this tends to wear down cylinder walls faster than normal. Engines need just the right mix of air and fuel to burn properly. If there's not enough air coming in, the combustion isn't complete, putting extra stress on everything inside the engine block. After months of running like this, mechanics often see early signs of wear along those cylinder walls. Most garages report seeing this issue more frequently in cars where owners neglect basic maintenance tasks. Checking air filters regularly makes a big difference in how long an engine lasts before needing major repairs or replacement parts.

Contaminant Infiltration Through Collapsed Filters

When air filters collapse, they let all sorts of bad stuff into the engine. Dust, sand, dirt particles these things get sucked right in where they shouldn't be. Left alone, this junk starts grinding against important engine parts. Think about it: pistons rubbing against gritty particles, bearings getting worn down over time. Eventually, this leads to expensive fixes nobody wants to deal with. Checking those filters regularly makes sense. Most mechanics recommend replacing them every 15,000 miles or so, depending on driving conditions. Keeping up with this simple task stops harmful materials from getting past the filter screen. For anyone who cares about their vehicle's longevity, proper filter maintenance isn't just good practice it's practically necessary for keeping engines running smoothly year after year.

Impact on Oil Filter Effectiveness

When an air filter gets dirty, it basically lets all sorts of junk get into the engine oil too. The oil filter just cant do its job properly if there are tons of particles floating around from bad air filtration. Mechanics see this all the time at shops across the country. They know that keeping air filters clean means cleaner oil overall, which helps engines run better for longer periods. Clean air really matters because dirty oil cant properly protect those expensive engine parts from wear and tear. Regular checks on air filters aren't just about following some maintenance schedule either they actually make a big difference in how long an engine lasts before needing major repairs or replacement.

Maintenance Best Practices

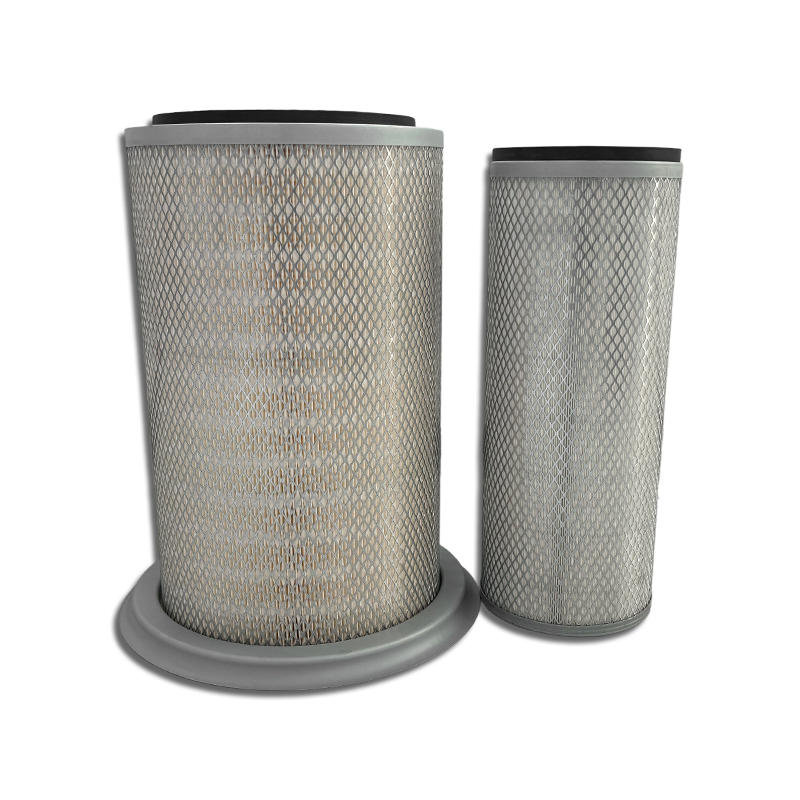

When to Replace Cabin vs Engine Air Filters

Getting air filters replaced when needed makes all the difference in keeping vehicles running smoothly. Most cabin air filters last around 15k to 25k miles before needing replacement, whereas engine air filters typically require changing somewhere between 12k and 15k miles mark, though this varies quite a bit based on actual driving habits. Several things influence how long filters stay effective including local air quality, how much someone drives weekly, plus whether they frequently hit dusty backroads or stick mainly to highways. People living near construction sites or industrial zones might find themselves replacing filters more often than those in cleaner environments. When unsure about exact timing, checking what car makers recommend remains smart practice. Mechanics also offer valuable insights since they see countless vehicles come through their shops daily and know firsthand what works best under different circumstances.

Syncing Filter Changes with Oil Filter Service

Getting air filters changed at the same time as oil filters makes good sense for anyone looking after their vehicle. When these tasks are done together, it creates an easier pattern to follow without forgetting important steps. The combined approach keeps engines running smoothly while saving money down the road since small problems don't get a chance to turn into bigger ones. Sticking to regular maintenance intervals actually boosts what a car is worth when it comes time to sell, plus it means fewer trips back to the mechanic for separate jobs. Most drivers find that this kind of synchronized maintenance works better in the long run and helps cars last much longer than those neglected between services.

Signs Your Air Conditioning Filter Needs Attention

Spotting when your car's AC filter needs work makes all the difference in how pleasant your rides feel. Musty smells coming through the vents, weaker airflow blowing out, or sudden allergy flare-ups during trips usually mean it's time to check that cabin air filter. When filters get grimy or blocked up, they basically ruin the air inside the car and cut down on comfort levels, turning what should be a relaxing drive into something frustrating. Most mechanics recommend looking at this filter every few months and swapping it out as needed to keep things fresh. Taking care of this simple maintenance task does more than just clean up the air we breathe while driving around town. It actually creates a better overall atmosphere inside the car, which means everyone gets to enjoy their journey more safely and comfortably without dealing with stuffy noses or irritated eyes.