The Critical Role of Truck Filters in Engine Protection

How Engine Air Filters Prevent Contaminant Ingestion in Long-Haul Operations

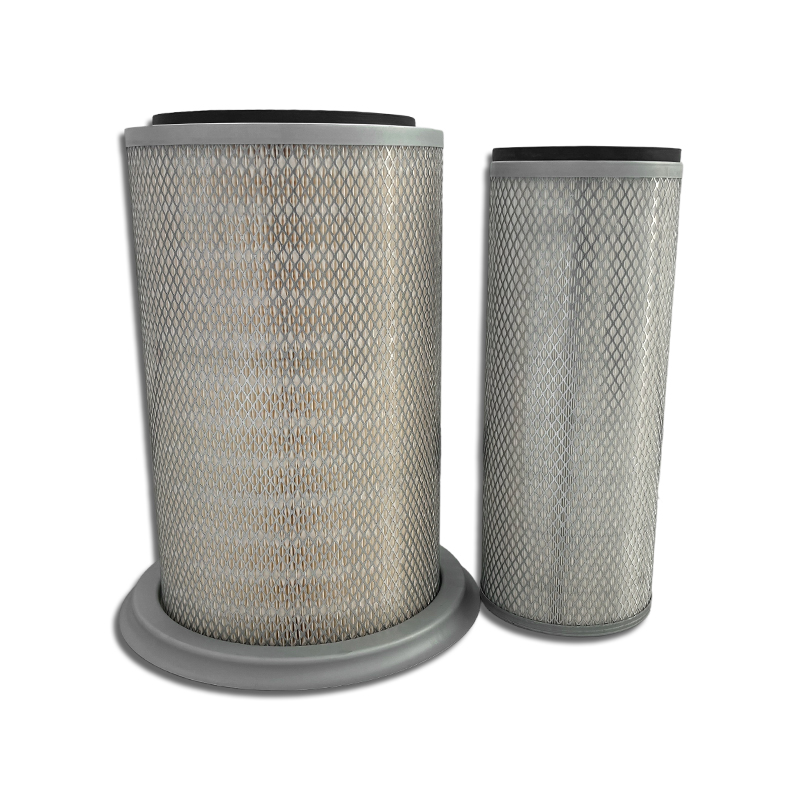

Air filters for engines serve as protection against all sorts of stuff floating around in the air - dust, pollen, bits of dirt and whatnot. When trucks are making those long trips through dry desert areas or near factories, good quality filters stop about 50 milligrams per cubic meter of dirty particles according to EPA data from last year. If a filter gets blocked or isn't working right, it can cut down on airflow by roughly 20 percent. That makes engines strain more which burns extra fuel. The newer filters that have several layers made with synthetic materials catch almost everything smaller than 10 microns, which means engines last longer too. Mechanics report seeing engines run better for anywhere between 18 to 24 months longer when proper filters are used during those extended road trips across country.

The Function of Oil Filters in Maintaining Lubrication Integrity Under Heavy Loads

Engines stay protected when oil filters remove all those pesky metal shavings, carbon buildups, and sludge from the system something that matters a lot for big rigs carrying over 80 thousand pounds. When these trucks are working hard under heavy loads, oil temps can actually go past 250 degrees Fahrenheit, which makes the oil lose its thickness faster than normal. The best high capacity spin on filters combine both cellulose and synthetic materials to catch about 95 percent of particles around 25 microns in size, which helps keep bearings from wearing down so quickly. Looking at real world fleet operations, we find that oil filters with bypass valves cut down on problems related to poor lubrication by roughly 37 percent according to Ponemon research from last year, especially noticeable when vehicles are making those tough mountain climbs.

Fuel Filters and Their Role in Safeguarding Diesel Engine Performance

The diesel fuel filter does a pretty important job stopping stuff like algae, water and sediment from clogging injectors these things cause about 15 percent of all breakdowns on the road according to Diesel Technology Forum data from last year. The newer coalescing filters can pull water out of fuel better than 93 percent of the time, and those multi layer filters catch almost all the tiny particles down to 5 microns. Fleets working in places where fuel quality varies quite a bit find that switching to 2 micron nano fiber filters makes a real difference they replace injectors less often about 65 percent fewer times actually and cut down NOx emissions by around 11 percent when running Tier 4 engines.

Key Types of Truck Filters: Air, Oil, Fuel, and DPF Systems

Comparative Analysis of Synthetic Filter Media Versus Cellulose in Air Intake Filters

Synthetic filter media outperforms cellulose in heavy-duty applications, offering 98.7% initial filtration efficiency compared to cellulose’s 95% (2023 Fleet Maintenance Report). Advantages include:

- Extended service life: Lasts 40% longer in high-dust environments

- Moisture resistance: Maintains integrity in humid conditions where cellulose degrades

- Flow optimization: Provides 15% lower air restriction, improving fuel economy

Micron Rating of Filters and Its Impact on Filtration Efficiency

Micron rating determines a filter’s ability to capture particulate matter, with most heavy-duty fuel filters rated between 10–30 microns. According to a 2024 Heavy-Duty Engine Study:

- Filters below 10 microns experience 18% faster pressure drop

- Filters above 30 microns allow 2.3x more abrasive particles into engines

Balancing micron ratings with flow requirements is essential—94% of premature injector failures are linked to improper fuel filtration.

Integration of Bypass Valves and Their Importance in Oil Filter Performance

Bypass valves prevent oil starvation during cold starts or filter clogs by allowing unfiltered oil to circulate temporarily. When properly calibrated, this failsafe reduces engine wear incidents by 67% in sub-zero operations. However, valves opening below 15 psi risk introducing contaminants into clean oil circuits, underscoring the need for precision engineering.

The Evolution of DPF Maintenance for Diesel Trucks in Modern Fleets

DPF (Diesel Particulate Filter) maintenance has evolved from reactive replacements to predictive cleaning cycles. Best practices now include:

- Active regeneration every 300–500 miles in urban driving

- Professional deep cleaning every 150,000 miles using thermal or aqueous methods

- Real-time pressure monitoring to detect 92% of ash buildup before power loss occurs

Proper DPF maintenance reduces fuel consumption by 2% and extends component life by 60,000 miles compared to neglectful approaches.

Maintenance Intervals and Duty-Cycle-Specific Filter Needs

Recommended Filter Service Intervals for Heavy-Duty Trucks Based on Manufacturer Guidelines

Most manufacturers recommend replacing truck filters every 15,000–25,000 miles under standard highway conditions:

- Oil filters: 15k–20k miles under normal loads (Penske 2023)

- Air filters: 25k–30k miles in low-dust environments

- Fuel filters: 10k–15k miles for modern diesel engines

These intervals assume moderate loads and temperatures, with industry leaders like Penske Truck Leasing adhering to meter-based replacement schedules to optimize fleet performance.

Differences in Filter Service Needs Based on Duty Cycle (Long-Haul vs. Short-Haul)

Long-haul trucks averaging 600+ daily miles require:

- Twice as many fuel filter replacements as regional haulers

- Air filter inspections every 10,000 miles in arid or dusty regions

- Oil filters with 30% higher contaminant capacity

Short-haul trucks face accelerated wear due to:

- 47% more cold starts per month (2023 Fleet Maintenance Report)

- Increased fuel filter clogging from frequent condensation cycles

- Faster air filter degradation in urban stop-and-go traffic

Controversy Analysis: Are Standard Maintenance Schedules Sufficient for Extreme Operating Environments?

A 2023 study of 3,200 mining and logging trucks revealed significant discrepancies between recommended and actual replacement needs:

| Standard Schedule | Actual Replacement Need | ||

|---|---|---|---|

| Oil Filters | 15k miles | – | 8k–10k miles |

| Air Filters | 25k miles | – | 12k–15k miles |

This gap fuels debate over whether universal guidelines overlook environmental stressors such as airborne silica or biodiesel contamination. While some fleets adopt 25% shorter intervals in harsh conditions, others caution against unnecessary replacements that may introduce installation errors.

Environmental and Operational Factors Affecting Truck Filter Performance

How Dust, Humidity, and Temperature Affect Air Filter Maintenance and Use of Air Restriction Monitors

Air filters just don't last as long in really dusty conditions. Studies from the National Institute for Occupational Safety show efficiency drops around 20% after only 5,000 miles driven, which means turbochargers and engine valves get worn out faster than normal. When humidity levels rise, things get even worse because dust particles stick together forming bigger chunks that clog up the system and make it harder for air to flow properly. This becomes especially problematic in hot desert areas where temperatures regularly go above 100 degrees Fahrenheit. The paper filters used in many systems actually start shrinking and developing cracks under these conditions, letting through anywhere between 12% to 18% more dirt compared to synthetic materials. That's why most commercial vehicle operators now install special monitoring equipment that watches for changes in air pressure. These devices send warnings when they detect pressure drops over 25 inches of water column since going beyond that point can seriously impact engine performance and horsepower output.

Fuel Filter Maintenance in Diesel Engines Exposed to Contaminated Fuel Sources

Diesel fuel contaminated with impurities brings about 3 to 5 times more water and particulate matter into engines in many developing areas. This means vehicle owners typically need to replace their fuel filters 2 or 3 times each year, compared to just once in cleaner environments according to the Department of Energy report from 2023. For transportation companies operating around busy ports or farms, installing water detection sensors along with coalescing filters has become absolutely necessary these days. The problem gets worse during rainy season when microbes multiply rapidly and sediment builds up significantly in these locations. Some best practices worth considering would be...

- Draining water separators every 150–200 engine hours

- Applying biocide additives after 72+ hours of fuel inactivity

- Matching micron ratings (2–4 microns for common-rail systems) to local fuel quality

Trucks using ASTM D975-compliant filters reduced injector wear by 40% even when exposed to high-sulfur diesel blends.

Signs of Failing Filters and Ensuring Proper Compatibility

Recognizing Signs of Fuel Filter Issues Such as Difficulty Starting and Increased Fuel Consumption

Operators often detect failing fuel filters through extended cranking (15+ seconds) and inconsistent acceleration under load. A 2023 field study found fleets experiencing 12–18% higher fuel consumption saw immediate improvement after replacing clogged filters—indicating restricted flow is starving the engine of necessary fuel volume.

Impact of Dirty Filters on Engine Performance: Reduced Horsepower and Higher Emissions

Contaminated filters prompt ECU recalibration, reducing horsepower by up to 9% and increasing particulate emissions by 300% according to emissions compliance research. This degradation occurs gradually, making real-time diagnostics essential for fleets in regulated zones.

Diagnostic Tools for Early Detection of Failing Truck Filter Systems

Modern OBD-II systems monitor fuel pressure differentials (ideal range: 4–6 PSI) and airflow restrictions, with telematics platforms issuing predictive alerts when thresholds are exceeded. Infrared particle counters enable in-service oil analysis, detecting bypass valve activation 500–800 miles earlier than traditional gauges.

Matching Filter Specifications (Size, Micron Rating, Bypass Valves) to Truck Make and Model

Filter compatibility studies show 23% of premature engine wear stems from mismatched micron ratings—such as using a 30-micron filter where a 10-micron unit is specified. Heavy-duty applications demand alignment between filter burst pressure (minimum 150 PSI) and OEM specs to avoid housing failures.

Industry Paradox: The Cost-Saving Myth of Non-OEM Filters in Heavy-Duty Applications

Aftermarket filters offer 40–60% upfront savings but carry a 2.8× higher risk of warranty-voiding injector damage. Over 100,000-mile intervals, genuine OEM filters prove 17% more cost-effective due to longer service life and sustained engine efficiency.

FAQ Section

Why are quality filters important for trucks?

Quality filters are crucial for preventing contaminants from entering the engine, maintaining lubrication integrity, and ensuring optimal performance. They help extend engine life and improve fuel efficiency.

How often should truck filters be replaced?

Under standard highway conditions, truck filters should be replaced every 15,000 to 25,000 miles, depending on the type of filter and manufacturer guidelines.

What are the signs of a failing fuel filter?

Signs of a failing fuel filter include extended cranking time during startup, inconsistent acceleration, and increased fuel consumption.

How do environmental factors affect filter performance?

Dust, humidity, and temperature can decrease filter efficiency, leading to faster wear and tear on engine parts. Monitoring equipment is often used to detect changes in air pressure that can affect engine performance.

Table of Contents

- The Critical Role of Truck Filters in Engine Protection

- Key Types of Truck Filters: Air, Oil, Fuel, and DPF Systems

- Maintenance Intervals and Duty-Cycle-Specific Filter Needs

- Environmental and Operational Factors Affecting Truck Filter Performance

-

Signs of Failing Filters and Ensuring Proper Compatibility

- Recognizing Signs of Fuel Filter Issues Such as Difficulty Starting and Increased Fuel Consumption

- Impact of Dirty Filters on Engine Performance: Reduced Horsepower and Higher Emissions

- Diagnostic Tools for Early Detection of Failing Truck Filter Systems

- Matching Filter Specifications (Size, Micron Rating, Bypass Valves) to Truck Make and Model

- Industry Paradox: The Cost-Saving Myth of Non-OEM Filters in Heavy-Duty Applications

- FAQ Section