Types of Heavy-Duty Truck Filters and Their Core Functions

Common Types of Truck Filters: Oil, Fuel, Air, Hydraulic, Cooling, and Air Dryer

Heavy-duty trucks rely on six critical filters to protect their systems:

- Oil filters cleanse abrasive particles from engine lubrication systems

- Fuel filters remove contaminants before diesel reaches injectors

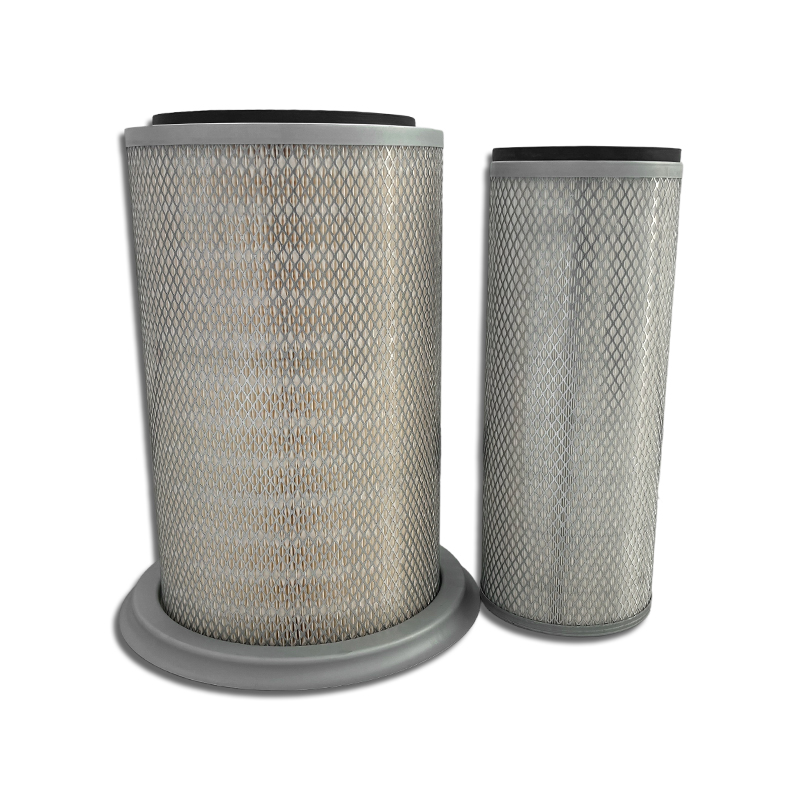

- Air filters block dust and debris from turbocharged engines

- Hydraulic filters maintain clean fluid in brake and lifting systems

- Cooling filters prevent silicate deposits in radiator loops

- Air dryer cartridges eliminate moisture from pneumatic brake lines

Each type intercepts specific contaminants at strategic points in the vehicle's workflow.

Function and System Placement of Each Filter Type in Heavy-Duty Trucks

Most oil filters attach right onto the engine block itself, making sure they process all the lubricant that circulates through the system. Fuel systems usually have two stages of filtering going on. First there's a sediment filter located close to where the fuel sits in the tank, then later on comes a finer micro glass filter positioned somewhere around the engine area. For hydraulic systems, special filters protect those expensive pump parts and valve assemblies within brake systems. Cooling filters work differently though, sitting inside radiator hoses to grab any scale buildup as it forms. Air dryer cartridges go into compressed air lines throughout vehicles, which helps keep those critical brake chamber areas free from rust damage over time. Getting these filters installed correctly matters a lot because when done properly, dirt and debris get caught early before they can mess up delicate internal parts down the road.

Matching Filtration Needs to Specific Trucking Operations (Long-Haul, Off-Road, Regional Delivery)

For long haul trucking companies, getting filters that hold lots of dirt between changes makes good business sense since every day lost to maintenance means lost revenue. When it comes to off road work though, things get really dusty out there. That's why many operators install those cyclonic pre cleaners first before going through multiple stages of air filtration systems. They need something serious against all that dirt kicked up by heavy machinery around construction sites. Regional delivery trucks face different challenges altogether. These vehicles start up so often in cold weather and run on biodiesel mixes which can leave water behind in fuel lines. So mechanics tend to spec out special fuel filters designed specifically for separating water from diesel better than standard models do. And down at the mines? Well most big rigs will have magnetic drain plugs added onto their hydraulic filters because metal particles floating around in oil systems just plain wear stuff out faster. Bottom line is matching filter specs to what each vehicle actually encounters day after day keeps engines running longer without spending extra bucks on unnecessary upgrades nobody needs.

Benefits of Integrated Filtration Systems for Overall Vehicle Efficiency

Filtration systems that work together help prevent those chain reactions we see so often in vehicle maintenance problems. Take contaminated oil as just one example it really speeds up injector wear over time. When all three main filters air, fuel and oil function properly together, engines run much better. Fuel efficiency actually improves by around 2 to 4 percent because combustion works right when everything's clean. Transmission systems don't slip as much since they're not dealing with dirty fluids anymore. And let's not forget about HVAC systems circulating cleaner air throughout the cabin makes a big difference too. Fleet managers who implement these monitoring systems report seeing about 30% fewer unexpected breakdowns according to a recent study from Commercial Vehicle Engineering in 2023. The bottom line is that taking this holistic approach not only makes parts last longer but also means mechanics spend less time chasing down random issues across different systems.

Key Selection Criteria for Optimal Truck Filter Performance

Critical factors in choosing a truck filter: micron rating, filter media, bypass valves, and compatibility

When choosing truck filters, there are several key considerations to keep in mind. The main factors include micron rating which determines what particle sizes get caught, the type of filter media used, how good the bypass valve is, and whether it works with original equipment manufacturer specs. According to data from SAE International released last year, filters rated at 10 microns manage to trap around 94 percent of abrasive particles. For those looking at media options, cellulose based filters tend to be more budget friendly, whereas synthetic alternatives offer better performance capturing nearly all contaminants down to 5 microns with their 98 percent efficiency rate. Another important feature worth noting is anti-drain back valves. These components help avoid problems when starting up after shutdown by keeping between 200 and 300 milliliters of oil inside the system, preventing the engine from running dry until lubrication can catch up properly.

Understanding micron rating and particle capture efficiency

Micron ratings determine filtration precision, but lower numbers aren't always better. A 15-micron fuel filter reduces injector wear by 62% compared to 30-micron filters in diesel engines (ASTM International, 2022), while maintaining optimal flow rates. Beta ratio measurements clarify true efficiency—a β₂⁵=200 filter removes 99.5% of 5-micron particles.

Bypass valves and anti-drain back mechanisms: protecting engine systems

Bypass valves activate at 8–15 PSI differential pressure to prevent oil starvation during cold starts. High-quality valves maintain lubrication flow even with 90% filter media clogging, critical for engines operating in dusty environments. Anti-drain back systems reduce metal-on-metal contact by keeping oil reservoirs in the filter housing.

Filter media showdown: cellulose vs. synthetic materials

| Property | Cellulose Media | Synthetic Media |

|---|---|---|

| Particle Retention | 85% @ 20 microns | 98% @ 10 microns |

| Service Life | 15,000–25,000 miles | 30,000–50,000 miles |

| Flow Resistance | 25% higher vs. synthetic | Optimized porous design |

| Cost | $18–$35 | $45–$80 |

Ensuring proper fit: matching filters to engine make, model, and OEM specs

A Caterpillar C15 requires 0.5mm tighter gasket tolerances than Detroit Diesel DD15 filters. Mismatched filters cause 23% of premature engine failures through improper sealing (Technology & Maintenance Council, 2023). Cross-reference OEM numbers using electronic catalogs to confirm thread pitch, relief valve specs, and flow rate compatibility.

High-Performance Filtration: Oil, Fuel, and Air Systems Compared

Engine Oil Filters With Synthetic Media for Extended Service Intervals

The newer synthetic media oil filters really beat the old cellulose ones hands down. They grab about 99 percent of all those tiny bits floating around in engine oil, even stuff as small as 20 microns, and still keep the oil flowing properly even when temps get crazy hot or cold. For trucks doing long hauls across country, these advanced filters mean service shops can stretch maintenance out between 25k and 50k miles. That cuts down on downtime at repair facilities by roughly 40%, which saves companies money and keeps their fleets moving. What makes synthetic media so good? Well, it just doesn't break down as fast as regular filter material does, especially during those frustrating stop-and-go city drives where engine oil temperature swings like a pendulum all day long.

Multi-Pass Efficiency and Beta Ratio: Measuring Oil Filter Performance

The industry-standard beta ratio (β) quantifies a filter's ability to trap particles across multiple passes through the media. A β≥200 rating indicates the filter removes 99.5% of 7-micron particles on each circulation cycle. Multi-pass efficiency tests simulate real-world conditions where oil circulates through the filter repeatedly, with premium synthetic filters achieving:

| Performance Metric | Synthetic Media Filter | Conventional Filter |

|---|---|---|

| 10-micron capture rate | 99.9% | 92% |

| Dirt holding capacity | 14 grams | 8 grams |

| Pressure drop at 180°F | 8 psi | 12 psi |

Fuel Filters and Water Separation in Diesel Engines: Preventing Contamination

Modern fuel filtration systems do more than just catch dirt particles they also separate out water, something really important for today's ultra low sulfur diesel fuels which tend to grow microbes over time. The best coalescing filters on the market can actually grab around 95% of those tiny water droplets down to 2 microns in size, which helps keep fuel injectors working properly instead of getting damaged from cavitation issues. Trucking companies across the country have seen dramatic improvements too many report cutting their fuel system problems by about three quarters after switching to these advanced systems that automatically drain collected water without needing manual intervention.

Primary vs. Secondary Fuel Filtration Stages and Fuel-Water Separator Function

Modern heavy-duty trucks use staged filtration for optimal protection:

Primary Fuel Filters

- Capture particles >30 microns

- Remove bulk water (free water separation)

- Protect fuel transfer pumps

Secondary Fuel Filters

- Filter down to 5 microns

- Remove emulsified water and microbial growth

- Guard high-pressure injection systems

Dry vs. Wet Air Filters: Performance, Maintenance, and Environmental Impact

Air filters coated with nanofibers can catch almost all 5-micron particles (about 99.97%) while still letting enough air flow through at around 1 inch of water pressure resistance for roughly 50 thousand miles of driving. Wet filters that use oil baths tell a different story though they need regular maintenance every month or so and create dangerous waste when cleaned with solvents. The EPA approved dry filter systems cut down on disposal expenses by nearly four fifths compared to their counterparts. Plus drivers might notice better gas mileage too something like half a percent improvement because these filters maintain steady airflow throughout operation rather than getting clogged up over time.

Extending Service Life and Maximizing Maintenance Efficiency

Recommended service intervals for oil, fuel, and air filters by application

For oil filters in big rigs, most long haul truckers change them somewhere between 15k and 25k miles depending on how hard they're working. Off road mining trucks? Those beasts might need new filters every 250 to 500 operating hours because they swallow so much dirt and dust. Fuel filters generally stick to manufacturer guidelines around 10k to 15k miles, but when running on biodiesel mixes or dealing with dirty fuel supplies, mechanics usually cut those intervals down by about 30%. Air filters are another story entirely. City delivery vans can sometimes stretch their air filters out to 50k miles since roads aren't so dusty there. But throw a construction vehicle into a cloud of concrete dust and expect to replace air filters every 15k at best. According to research from the American Transportation Research Institute back in 2022, companies that actually paid attention to these specific maintenance needs saw almost a third drop in engine breakdowns across their fleet.

Using restriction indicators and condition-based monitoring for optimal maintenance

Today's truck filters come equipped with restriction sensors that send warnings to the dashboard whenever air flow falls under 25 inches of water column or fuel pressure goes over 12 psi. Some of the newer systems connect these warnings directly to telematics platforms, which can automatically schedule maintenance appointments. According to Frost & Sullivan from last year, companies that adopted this technology saw their unexpected repairs drop by around 41%, with about half of all fleets reporting improvements. For those looking even deeper into maintenance efficiency, oil analysis programs capable of detecting particles smaller than 10 microns allow for smarter replacement decisions. These programs help extend filter life by approximately 18% on average, beating out traditional fixed interval replacements that often lead to either premature changes or risky delays.

How proper filtration reduces wear and supports long-term engine health

Fuel filters that capture around 98 percent of particles larger than 4 microns help stop injectors from wearing down over time. Injector damage actually makes up about two thirds of all diesel engine rebuild work according to research from NREL back in 2021. When it comes to air filters, those keeping 99.9% efficiency at the 10 micron level make a big difference too. They cut down on cylinder bore polishing caused by tiny abrasive particles, something that leads to roughly one fifth power loss in older engines. For hydraulic systems, staying within an ISO cleanliness code below 10 is absolutely critical. This standard helps eliminate most pump failures that happen because of microscopic wear particles building up inside the system components.

Strategies to extend filter life without compromising performance

- Pre-clean air intake housings weekly using compressed air at <30 psi

- Install fuel/water separators with automatic drainage valves

- Use synthetic media upgrades for 15–20% longer oil filter serviceability

- Pair spin-on filters with magnetic drain plugs to trap ferrous debris

- Avoid engine idling beyond OEM recommendations to minimize soot accumulation

Fleets implementing these strategies report 28% longer average filter lifespans while maintaining 97%+ filtration efficiency across all systems.

OEM vs. Aftermarket Truck Filters: Cost, Quality, and Fleet Considerations

Pros and Cons of OEM Versus Aftermarket Truck Filters

Truck filters made by OEMs Original Equipment Manufacturers are designed specifically for each engine model, so they fit just right and work reliably since they've been tested thoroughly. But here's the catch: these genuine parts typically set businesses back anywhere from 35 to almost 65 percent extra compared to what aftermarket options cost, based on those latest 2023 fleet maintenance studies we've seen floating around. On the flip side, aftermarket filters give folks more room to play with prices and sometimes even bring new ideas to the table. Some of the newer synthetic media filters out there actually grab around 98 percent of particles, which isn't far off from what OEM standards require. Still worth noting though, when it comes to third party brands, quality can be all over the map. The cheaper stuff tends to let too many contaminants through, potentially raising problems in diesel engines by as much as forty percent if not careful.

Manufacturer Recommendations and Warranty Implications

The majority of engine makers insist on original equipment manufacturer (OEM) filters if they want their warranty to stay valid. According to research published last year, nearly 8 out of 10 rejected warranty cases had something to do with aftermarket parts not hitting those OEM standards. For companies running fleets, switching to non-OEM filters can mean losing protection on important parts such as fuel injectors or turbochargers when problems arise. Before going against what the factory recommends, fleet managers should check whether their suppliers hold proper ISO certifications and have documentation proving their products match OEM specifications. This extra step might save thousands down the road.

Cost-Benefit Analysis: Premium Filters vs. Budget Alternatives

| Factor | OEM Filters | Aftermarket Filters |

|---|---|---|

| Initial Cost | $48–$120 | $22–$75 |

| Avg. Service Life | 25,000–35,000 miles | 15,000–25,000 miles |

| Warranty Compliance | Full coverage | Limited/No protection |

| Contamination Risk | <1% failure rate | 4–9% failure rate |

While aftermarket filters reduce upfront costs by $210 per truck annually, fleets report 18% higher maintenance costs over three years due to shorter replacement cycles.

Balancing Upfront Cost with Long-Term Savings and Reliability

When it comes to engines still covered by warranty or those running in tough conditions such as mines or refrigeration units, going with OEM filters makes sense. Older trucks though? There are good alternatives out there. Aftermarket filters that meet either API-1581 or ISO 4548 standards actually save money over time. We're talking around $1,740 saved each year per truck without any real drop in how long they last. And here's something else worth mentioning: when companies buy these filters in bulk or get special warranties tailored for their entire fleet from trusted aftermarket manufacturers, the price difference between OEM and quality aftermarket just keeps getting smaller and smaller.

FAQs on Heavy-Duty Truck Filters

What are the types of filters used in heavy-duty trucks?

Heavy-duty trucks use oil filters, fuel filters, air filters, hydraulic filters, cooling filters, and air dryer cartridges to protect various systems.

Why is it important to match filters to specific trucking operations?

The right filters can help enhance performance based on the specific challenges faced in different operations like long-haul, off-road, or regional delivery.

How does integrated filtration benefit overall vehicle efficiency?

Integrated filtration ensures better performance, improved fuel efficiency, and reduces unexpected breakdowns by working across multiple systems.

What should I consider when choosing a truck filter?

Key considerations include micron rating, filter media, bypass valves, and compatibility with original equipment manufacturer specifications.

What is the difference between OEM and aftermarket filters?

OEM filters are tailored for specific engines but cost more, whereas aftermarket filters offer price flexibility but vary in quality.

Table of Contents

-

Types of Heavy-Duty Truck Filters and Their Core Functions

- Common Types of Truck Filters: Oil, Fuel, Air, Hydraulic, Cooling, and Air Dryer

- Function and System Placement of Each Filter Type in Heavy-Duty Trucks

- Matching Filtration Needs to Specific Trucking Operations (Long-Haul, Off-Road, Regional Delivery)

- Benefits of Integrated Filtration Systems for Overall Vehicle Efficiency

-

Key Selection Criteria for Optimal Truck Filter Performance

- Critical factors in choosing a truck filter: micron rating, filter media, bypass valves, and compatibility

- Understanding micron rating and particle capture efficiency

- Bypass valves and anti-drain back mechanisms: protecting engine systems

- Filter media showdown: cellulose vs. synthetic materials

- Ensuring proper fit: matching filters to engine make, model, and OEM specs

-

High-Performance Filtration: Oil, Fuel, and Air Systems Compared

- Engine Oil Filters With Synthetic Media for Extended Service Intervals

- Multi-Pass Efficiency and Beta Ratio: Measuring Oil Filter Performance

- Fuel Filters and Water Separation in Diesel Engines: Preventing Contamination

- Primary vs. Secondary Fuel Filtration Stages and Fuel-Water Separator Function

- Dry vs. Wet Air Filters: Performance, Maintenance, and Environmental Impact

- Extending Service Life and Maximizing Maintenance Efficiency

- OEM vs. Aftermarket Truck Filters: Cost, Quality, and Fleet Considerations

-

FAQs on Heavy-Duty Truck Filters

- What are the types of filters used in heavy-duty trucks?

- Why is it important to match filters to specific trucking operations?

- How does integrated filtration benefit overall vehicle efficiency?

- What should I consider when choosing a truck filter?

- What is the difference between OEM and aftermarket filters?