The Critical Role of Air Filters in Commercial Fleet Engine Performance

Commercial fleet engines depend on air filters to maintain optimal performance and longevity. These components serve as the first defense against airborne contaminants while directly influencing fuel efficiency and operational costs. Below, we break down their critical functions and compare popular filter types used in heavy-duty trucks.

How Air Filters Protect Engines from Damaging Contaminants

The job of air filters is to catch all that dirt, dust, and junk before it gets into the engine's combustion chambers where it does real damage. Just think about this: one gram of stuff getting sucked in can wear down those cylinder walls and piston rings after only 500 miles driven, which means the engine starts breaking down faster maybe even 15% quicker according to SAE International from last year. These days, modern filters have multiple layers that grab particles down to around 5 microns in size something like 1/10th as thick as a human hair. That matters because smaller particles mean cleaner oil stays in circulation longer and valves don't get eroded as fast either.

Impact of Air Filter Efficiency on Fuel Economy and Emissions

When filters get clogged or are just plain poor quality, they block airflow and make engines strain more, which can bump up fuel consumption somewhere between 3 to maybe even 7 percent. On the flip side, those top notch high efficiency filters keep the right balance of air and fuel going into the engine, cutting down on harmful particles in exhaust gases by around twenty two percent according to EPA guidelines from last year. Trucking companies that switch to these better filters often see their wallets benefit too. One industry source mentioned saving approximately twelve hundred dollars each year per vehicle simply by installing filters capable of holding over ninety nine percent of dust and debris.

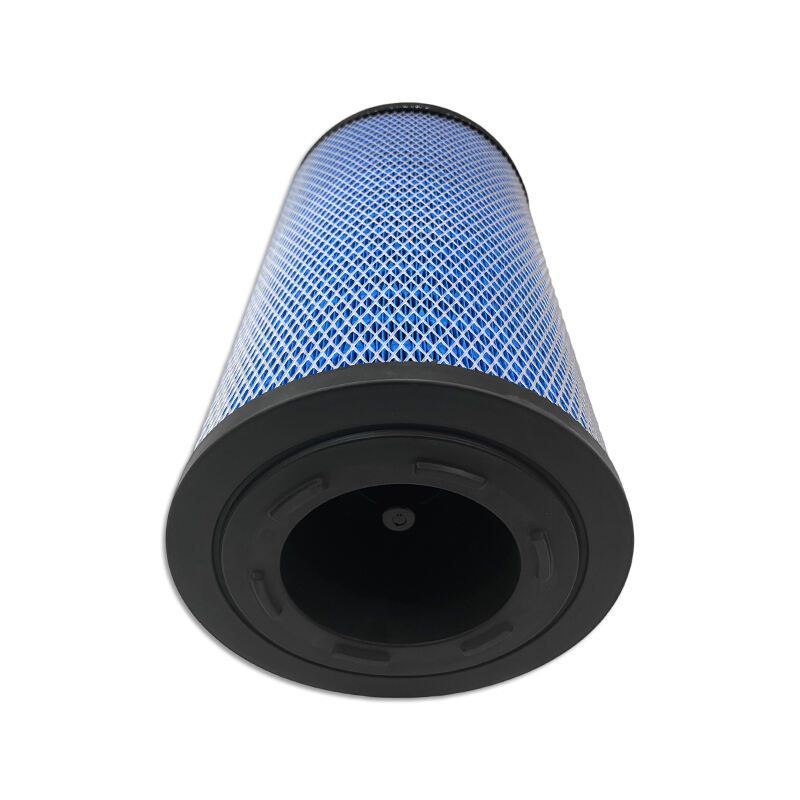

Common Types of Air Filters in Commercial Trucks: Paper vs. Synthetic Gauze

| Feature | Paper Filters | Synthetic Gauze Filters |

|---|---|---|

| Initial Cost | $40–$80 | $90–$150 |

| Lifespan | 15,000–25,000 miles | 50,000–75,000 miles |

| Cleaning Reusability | Not recommended | Up to 6 times |

| Best For | Urban/low-dust routes | Desert/mining operations |

Synthetic gauze filters dominate harsh environments due to their higher dust capacity and washable design, though paper remains cost-effective for fleets in moderate conditions.

Developing a Data-Driven Air Filter Maintenance Schedule

Manufacturer-Recommended Replacement Intervals and Fleet Compliance

Getting the most out of air filters in commercial vehicles means following the replacement schedule recommended by the manufacturer. The folks who make the original equipment, known as OEMs, establish when filters should be changed based on extensive tests done in lab settings. These intervals usually range somewhere between 25 thousand to 50 thousand miles. But according to recent data from Fleet Maintenance Report 2023, around 37 percent of fleet managers actually go beyond these recommendations just to save money on parts. What they might not realize is that this practice can lead to roughly a 15% decrease in fuel economy over time. Sticking with the manufacturer's timeline keeps air flowing properly through the system, helps avoid early wear on engines, and makes sure any warranty coverage remains valid for those unexpected breakdowns down the road.

Mileage-Based and Time-Based Air Filter Replacement Guidelines

Two primary strategies govern air filter replacements:

- Mileage-based systems work well for high-mileage fleets but fail to account for idling or low-speed urban driving

- Time-based schedules (e.g., quarterly replacements) better suit vehicles exposed to seasonal debris or prolonged storage

Leading logistics providers combine both approaches, replacing air filters every 40,000 miles or 12 months–whichever comes first. This hybrid model reduces contamination-related breakdowns by 28% compared to single-metric systems.

Integrating Air Filter Checks Into Comprehensive Fleet Maintenance Routines

Progressive fleets embed air filter inspections into multi-point maintenance workflows. A three-stage protocol optimizes results:

- Pre-trip inspections: Quick visual checks for visible damage

- Scheduled servicing: Precision cleaning with compressed air tools

- Predictive analytics: Monitoring engine performance metrics for airflow restrictions

This integration reduces unscheduled maintenance by 32% while extending average filter lifespans by 18% compared to isolated replacement strategies.

Adapting Air Filter Maintenance to Operating Environments and Conditions

How Dust, Dirt, and Harsh Climates Accelerate Air Filter Degradation

Air filters on commercial vehicles tend to wear out much quicker when exposed to environments loaded with particles. Take desert regions for instance where fleets deal with all that silica rich sand which wears down filter materials about three times faster than regular city road dust according to SAE research from last year. Then there are coastal areas where salt particles mix with moisture creating these nasty corrosive buildups on filters. And don't even get me started on Arctic conditions that literally make paper filters brittle and prone to cracking once temperatures drop below minus 20 degrees Celsius. All these environmental challenges cut down how much dirt filters can hold by somewhere between forty to sixty percent relative to normal conditions. The result? More debris gets sucked into engines instead of being caught, which obviously isn't good news for maintenance costs or engine longevity.

Regional Adjustment of Maintenance Schedules: Desert vs. Urban Fleets

For fleets operating across the Southwest United States, air filters need replacing roughly every 8,000 to 10,000 miles, compared to around 15,000 miles for those delivering goods in cities. The difference? Well, Arizona experiences these massive dust storms that pack an incredible 12,000 micrograms per cubic meter of PM10 particles. That's actually 24 times what the Environmental Protection Agency considers safe for daily exposure. According to research published last year, trucks running out of Phoenix required almost twice as many filter replacements as their Seattle-based equivalents. But here's something interesting: despite all that extra maintenance work, these Southwest vehicles managed to get about 9 percent better fuel economy simply because they were kept in better condition overall.

Case Study: Air Filter Lifespan Comparison in Extreme Operating Conditions

A 12-month trial with 200 Class 8 trucks revealed stark differences:

- Mining trucks (West Texas): 5,200-mile average filter life

- Refrigerated transports (Midwest): 11,000-mile lifespan

- Port drayage vehicles (California): 7,800-mile replacement cycles

The mining group showed 23% higher engine wear markers despite 35% shorter intervals, proving environmental adaptation requires both schedule adjustments and filter media upgrades.

Cleaning vs. Replacing Air Filters: Best Practices for Long-Term Efficiency

Methods and misconceptions around cleaning heavy-duty air filters

Compressed air blowing is still widely used to clean reusable filters, but many top manufacturers are starting to push for liquid based cleaning instead since it helps keep those fibers intact. According to research from ASE back in 2023, when people don't clean properly, their filters lose between 18 and 27 percent efficiency compared to what they should be doing out of the box. Looking at actual field reports too, about 43 percent of folks running fleets think that if a filter looks clean then it must work fine. What they miss though are those tiny blockages in the pores that aren't visible to the naked eye but seriously impact performance over time.

Risks of reusing cleaned filters and loss of filtration efficiency

When synthetic filters go through multiple cleaning cycles, they start breaking down. The fibers separate and the adhesives holding everything together begin to fail. According to ASE tests, filters that have been cleaned let about 14 percent more 10-micron particles pass through into engine compartments than brand new ones do. Things get even worse in really dusty conditions. After just three cleanings, particulate bypass jumps all the way to 31%. This leads to faster wear on cylinder walls too, costing fleet operators around twelve cents extra per mile driven based on recent monitoring data from Commercial Fleet Analytics in their 2023 report.

Performance data: Dust holding capacity after cleaning washable filters

| Cleaning Method | Initial Capacity (grams) | Post-Clean Capacity | Efficiency Loss |

|---|---|---|---|

| Reverse Air Flow | 800 | 620 (-22.5%) | 18% |

| Chemical Immersion | 800 | 710 (-11.3%) | 9% |

| Ultrasonic Cleaning | 800 | 745 (-6.9%) | 5% |

Data source: 2024 Heavy-Duty Filtration Systems Report

Washable air filters: Advantages and limitations for commercial fleets

While washable filters reduce replacement part costs by 60% annually, their 3–5 year lifespan makes them impractical for fleets exceeding 150,000 annual miles. Field studies show optimal cost-benefit occurs in urban delivery fleets with controlled particulate exposure, whereas cross-country haulers experience 40% faster performance degradation compared to disposable filters.

Monitoring Air Filter Condition to Optimize Replacement Timing

Using Vacuum Gauges for Real-Time Air Filter Efficiency Monitoring

Vacuum gauges give quick insights into how well air filters are working by checking the pressure difference across the filter material. Most engine makers set a limit around 25 inches of mercury (inHg) for when filters need replacing. Once the vacuum reading goes past that mark, it's time to swap out the filters before dirt starts getting through. This approach makes a real difference in operations. According to some recent data from over 12 thousand commercial trucks tracked in 2023, companies that monitor their filters this way see about an 18 percent drop in unexpected downtime compared to those who just replace filters on a schedule regardless of condition.

Oil Analysis as an Indirect Method to Assess Air Filter Performance

Checking engine oil samples regularly provides another way to see how well air filters are working. When there's more dirt building up in the oil, measured by those ISO numbers everyone talks about, it usually means the filters aren't doing their job properly anymore. Some research from last year looked at almost 900 trucks and discovered something interesting: when mechanics checked the oil instead of just looking at the filters, they spotted problems with worn out filters about a quarter sooner. That early warning can save money because it stops tiny particles from wearing down expensive parts inside the engine over time.

Field Testing and Diagnostic Tools for Large-Scale Fleet Management

Advanced diagnostic technologies enable systematic air filter condition monitoring across entire fleets:

| Monitoring Method | Key Metric | Operational Benefit |

|---|---|---|

| Vacuum Gauge Analysis | Pressure differential (inHg) | Real-time performance assessment |

| Oil Particulate Counting | ISO 4406 contamination code | Early failure detection |

| Ultrasonic Leak Testing | Airflow consistency | Identifies housing seal failures |

Combining these approaches allows maintenance teams to extend filter service life by 35% in normal conditions while triggering proactive replacements in high-dust environments, achieving optimal balance between cost efficiency and engine protection.

FAQ Section

What are air filters in commercial trucks used for?

Air filters in commercial trucks are used to prevent dirt, dust, and other particles from entering the engine's combustion chambers, thereby protecting engine components and improving fuel efficiency.

How does air filter efficiency affect fuel economy?

Efficient air filters maintain optimal airflow, which can reduce fuel consumption by preventing the engine from straining due to clogged filters. This can lead to savings on fuel and improved emissions.

What types of air filters are commonly used in commercial trucks?

Common air filter types include paper filters, which are cost-effective for moderate conditions, and synthetic gauze filters, which are preferred in harsh environments due to their washable design and higher dust capacity.

How often should air filters be replaced in commercial fleets?

Air filters should be replaced according to manufacturer recommendations, typically every 25,000 to 50,000 miles, but conditions such as dust-heavy environments may necessitate more frequent replacements.

Table of Contents

- The Critical Role of Air Filters in Commercial Fleet Engine Performance

- Developing a Data-Driven Air Filter Maintenance Schedule

- Adapting Air Filter Maintenance to Operating Environments and Conditions

- Cleaning vs. Replacing Air Filters: Best Practices for Long-Term Efficiency

- Monitoring Air Filter Condition to Optimize Replacement Timing