ประเภทของตัวกรองรถบรรทุกและฟังก์ชันหลักของมัน

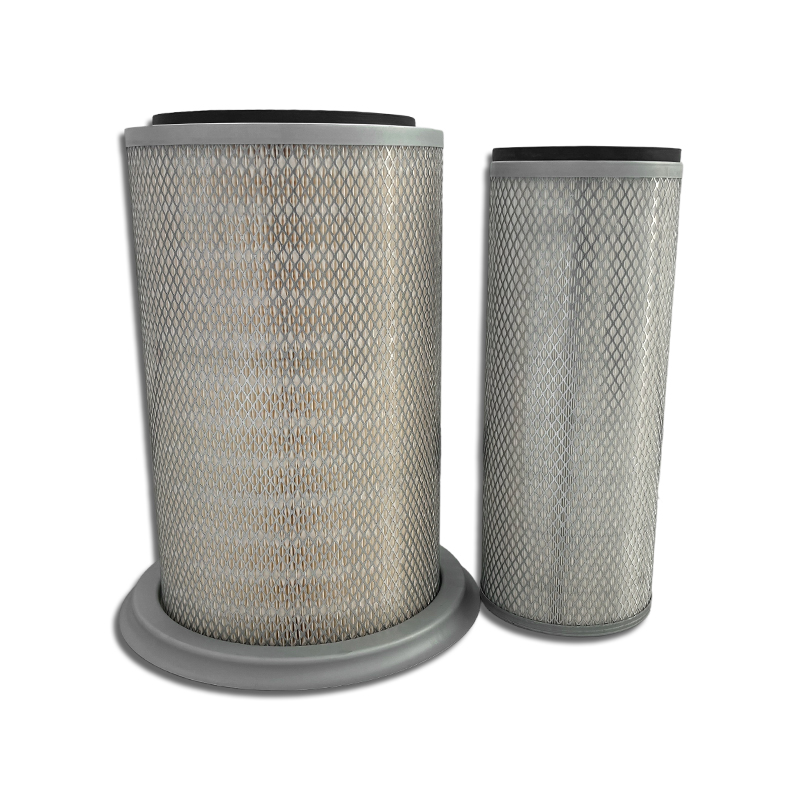

ตัวกรองอากาศสำหรับรถบรรทุก: การคุ้มครองสุขภาพของเครื่องยนต์

ตัวกรองอากาศสำหรับรถบรรทุกมีความสำคัญอย่างมากในการรักษาสุขภาพของเครื่องยนต์ เนื่องจากมันช่วยป้องกันไม่ให้ฝุ่นและสิ่งสกปรกเข้าไปในที่ที่มันไม่ควรจะอยู่ หากปราศจากการป้องกันนี้ เครื่องยนต์มักจะสึกหรอเร็วขึ้น เพราะอนุภาคเล็กๆ เหล่านี้จะก่อให้เกิดความเสียหายขึ้นในระยะยาว การเปลี่ยนตัวกรองเหล่านี้อย่างสม่ำเสมอจะช่วยให้อากาศไหลเวียนเข้าสู่เครื่องยนต์ได้อย่างเหมาะสม ซึ่งส่งผลอย่างมากต่อสมรรถนะและการใช้งานเครื่องยนต์ที่ยาวนานขึ้น มีงานวิจัยบางชิ้นแสดงให้เห็นว่าเมื่อตัวกรองอากาศยังคงสะอาด ประสิทธิภาพการใช้เชื้อเพลิงอาจดีขึ้นได้ราวๆ 10 เปอร์เซ็นต์ ดังนั้นจึงเห็นได้ว่าการดูแลรักษาตัวกรองเหล่านี้มีความสำคัญอย่างแท้จริง รถบรรทุกแต่ละคันยังต้องการตัวกรองอากาศที่แตกต่างกันอีกด้วย สิ่งที่ใช้ได้ผลดีกับรุ่นหนึ่ง อาจไม่เหมาะกับอีกรุ่นหนึ่ง ดังนั้นการตรวจสอบข้อมูลจำเพาะที่จำเป็นสำหรับรถแต่ละคันจึงเป็นสิ่งที่จำเป็นอย่างมาก หากผู้ใช้ต้องการให้รถบรรทุกของตนทำงานได้อย่างราบรื่นตลอดหลายปี

ตัวกรองเชื้อเพลิงสำหรับรถบรรทุก: การเพิ่มประสิทธิภาพการเผาไหม้

ตัวกรองเชื้อเพลิงมีบทบาทสำคัญในการปกป้องเครื่องยนต์โดยการกำจัดสิ่งสกปรกและเศษสิ่งแปลกปลอมออกจากเชื้อเพลิงก่อนที่จะเข้าสู่ห้องเผาไหม้ กระบวนการนี้มีผลอย่างมากต่อประสิทธิภาพการเผาไหม้ของเครื่องยนต์และช่วยลดการปล่อยไอเสียที่เป็นอันตราย สำนักงานคุ้มครองสิ่งแวดล้อม (EPA) รายงานว่าเมื่อตัวกรองเชื้อเพลิงสกปรก อาจส่งผลเสียต่อสมรรถนะของเครื่องยนต์และทำให้การปล่อยไอเสียแย่ลงด้วย การรักษาความสะอาดของตัวกรองจึงมีความสำคัญอย่างมากหากผู้ใช้งานต้องการให้เครื่องยนต์ทำงานได้อย่างราบรื่น นอกจากนี้ ยังควรทราบว่ารถบรรทุกแต่ละชนิดต้องใช้ตัวกรองเชื้อเพลิงที่แตกต่างกันออกไป ขึ้นอยู่กับข้อกำหนดของรุ่น ดังนั้นการรู้ว่าตัวกรองแบบใดเหมาะกับรถของคุณที่สุด จะช่วยให้รักษาระดับสมรรถนะที่ดีในระยะยาว การตรวจสอบและเปลี่ยนตัวกรองเป็นประจำจะช่วยให้ระบบเชื้อเพลิงทำงานได้อย่างมีประสิทธิภาพ ซึ่งหมายถึงการประหยัดน้ำมันและยืดอายุการใช้งานของเครื่องยนต์โดยรวม

ตัวกรองน้ำมัน: การปกป้องระบบหล่อลื่นของเครื่องยนต์

ตัวกรองน้ำมันมีหน้าที่สำคัญในการกรองสิ่งสกปรกและเศษสิ่งแปลกปลอมออกจากน้ำมันเครื่อง ซึ่งช่วยให้เครื่องยนต์ทำงานได้อย่างราบรื่น และลดการสึกหรอที่ไม่จำเป็นลงเมื่อเวลาผ่านไป เมื่อผู้ขับขี่เปลี่ยนถ่ายน้ำมันอย่างสม่ำเสมอและเปลี่ยนตัวกรองตามที่จำเป็น ก็เท่ากับเป็นการช่วยยืดอายุการใช้งานของเครื่องยนต์ไปในตัว มีงานวิจัยบางชิ้นชี้ให้เห็นตัวเลขที่ค่อนข้างน่าตกใจเช่นกันว่า น้ำมันที่สกปรกสามารถก่อให้เกิดการสึกหรอในชิ้นส่วนเครื่องยนต์ได้มากกว่าประมาณ 30% เมื่อเทียบกับน้ำมันที่สะอาด สิ่งนี้เข้าใจได้เมื่อพิจารณาว่าชิ้นส่วนโลหะภายในเครื่องยนต์ต้องเสียดสีกันอย่างไร โดยเฉพาะสำหรับเจ้าของรถบรรทุกแล้ว การเลือกใช้ตัวกรองคุณภาพดีที่ออกแบบมาสำหรับรุ่นรถของตนเองโดยเฉพาะนั้นมีความสำคัญมาก เพราะตัวกรองที่เหมาะสมจะช่วยทำให้น้ำมันไหลเวียนภายในระบบได้อย่างมีประสิทธิภาพมากยิ่งขึ้น น้ำมันที่สะอาดหมายถึงแรงเสียดทานระหว่างชิ้นส่วนที่เคลื่อนไหวลดลง ทำให้เครื่องยนต์มีอายุการใช้งานยาวนานขึ้นและประสิทธิภาพการทำงานดีขึ้นโดยรวม กลไกส่วนใหญ่ที่ให้คำแนะนำจะบอกกับทุกคนว่า ขั้นตอนการบำรุงรักษาง่ายๆ ขั้นตอนนี้สามารถช่วยประหยัดค่าใช้จ่ายในระยะยาวได้ เนื่องจากช่วยป้องกันปัญหาใหญ่ที่อาจเกิดขึ้นในอนาคต

ไส้กรองอากาศในห้องโดยสาร: เพิ่มความสะดวกสบายให้ผู้ขับขี่

ตัวกรองอากาศในห้องโดยสารที่มีคุณภาพช่วยให้อากาศภายในรถบรรทุกสะอาดได้อย่างมีประสิทธิภาพ ตัวกรองจะช่วยดักจับสิ่งต่างๆ เช่น ละอองเกสร ฝุ่น และสิ่งสกปรกอื่นๆ ที่ลอยอยู่ระหว่างการขับขี่ สำหรับผู้ขับขี่ที่ต้องเดินทางเป็นประจำทุกวัน สิ่งนี้ช่วยให้สามารถหายใจได้สะดวกขึ้นในระหว่างการเดินทางไกลข้ามประเทศ ช่างเทคนิคส่วนใหญ่แนะนำให้เปลี่ยนตัวกรองเหล่านี้ทุกประมาณ 12,000 ถึง 15,000 ไมล์ เพื่อให้ตัวกรองทำงานได้อย่างเต็มประสิทธิภาพ ไม่มีใครอยากสูดอากาศที่ไม่สดชื่น หรือกลิ่นแปลกๆ ที่ลอยอยู่ในห้องโดยสาร ตัวกรองที่ดีไม่เพียงแค่กรองสิ่งสกปรกเท่านั้น แต่ยังช่วยให้ระบบทำความร้อนและระบบปรับอากาศทำงานได้มีประสิทธิภาพมากยิ่งขึ้น ทำให้ห้องโดยสารโดยรวมน่านั่งขึ้นสำหรับทุกคนที่อยู่ในรถ คนขับที่ไม่ต้องหายใจเอาฝุ่นสกปรกเข้าไป มักจะมีความสุขมากขึ้นโดยรวม และคนขับที่มีความสุขก็มักจะทำงานได้มีประสิทธิภาพมากกว่า

วิธีที่ฟิลเตอร์รถบรรทุกส่งผลกระทบโดยตรงต่อสมรรถนะของยานพาหนะ

อายุการใช้งานของเครื่องยนต์และการลดการสึกหรอ

เมื่อตัวกรองของรถบรรทุกทำงานได้อย่างเหมาะสม ก็หมายถึงการสึกหรอของเครื่องยนต์ที่ลดลง และช่วยให้รถบรรทุกสามารถใช้งานบนท้องถนนได้นานหลายปีแทนที่จะเสียหายตั้งแต่ระยะสั้น ข้อมูลจากการสำรวจของช่างเครื่องและผู้ประกอบการรถบรรทุกยืนยันเรื่องนี้ซ้ำแล้วซ้ำเล่าว่า การยึดมั่นตามแผนการบำรุงรักษาช่วยลดปัญหาการเสียหายของรถได้ ประเด็นหลักคือ การเปลี่ยนตัวกรองอย่างสม่ำเสมอ ตัวกรองใหม่ช่วยให้น้ำมันไหลผ่านเครื่องยนต์ได้ดีขึ้น และช่วยรักษาอุณหภูมิให้เย็นลงเมื่อเครื่องยนต์รับภาระหนักจนร้อนขึ้น แท้จริงแล้ว ผู้ขับขี่ส่วนใหญ่รู้เรื่องนี้ดีอยู่แล้ว แต่กลับละเลยเพราะมักลืมบ่อย ๆ อย่างไรก็ตาม การเปลี่ยนตัวกรองอย่างสม่ำเสมอยังผลให้เครื่องยนต์มีอายุการใช้งานที่ยาวนานขึ้นมาก ก่อนที่จะจำเป็นต้องซ่อมแซมใหญ่หรือเปลี่ยนชิ้นส่วนใหม่

ประสิทธิภาพของเชื้อเพลิงและการควบคุมมลพิษ

การบำรุงรักษาตัวกรองอากาศของรถบรรทุกให้อยู่ในสภาพที่ดี ช่วยให้เชื้อเพลิงเผาไหม้ได้ดีขึ้น และช่วยลดการใช้เชื้อเพลิงโดยรวม ตามรายงานของสำนักคุ้มครองสิ่งแวดล้อมสหรัฐฯ (EPA) ระบุว่า ตัวกรองอากาศที่สะอาดจะช่วยให้เป็นไปตามมาตรฐานการปล่อยมลพิษที่เข้มงวด เนื่องจากตัวกรองที่อุดตันจะปล่อยมลพิษออกมาเกินกว่าที่ควร เมื่อผู้ประกอบการกองรถบรรทุกเลือกใช้ตัวกรองคุณภาพดีในการเปลี่ยน รถบรรทุกของพวกเขาจะปล่อยก๊าซเรือนกระจกได้น้อยลง ซึ่งเป็นประโยชน์ต่อสิ่งแวดล้อมอย่างชัดเจน นอกจากนี้ยังช่วยประหยัดค่าเชื้อเพลิงได้อีกด้วย แต่ยังมีอีกมุมหนึ่งที่ควรพิจารณา คือเครื่องยนต์ที่เผาไหม้สะอาดยิ่งขึ้นจะช่วยลดการสะสมของเขม่าในระบบ ซึ่งช่างต่างรู้ดีจากการปฏิบัติงานจริง สำหรับบริษัทที่บริหารกองรถดีเซลขนาดใหญ่ การเปลี่ยนตัวกรองอย่างสม่ำเสมอไม่ใช่เพียงแค่การปฏิบัติตามกฎหมายเท่านั้น แต่ยังกลายเป็นส่วนหนึ่งของกลยุทธ์ทางธุรกิจที่ช่วยให้ธุรกิจดำเนินไปอย่างยั่งยืน รักษาค่าใช้จ่ายในการดำเนินงานให้อยู่ในระดับที่ควบคุมได้ พร้อมกับรักษาสิ่งแวดล้อมไปด้วยในตัว

ตารางการบำรุงรักษาและการแสดงสัญญาณเปลี่ยนฟิลเตอร์

ช่วงเวลาแนะนำสำหรับฟิลเตอร์อากาศและเชื้อเพลิง

การยึดมั่นในมาตรฐานอุตสาหกรรมมีความสำคัญอย่างมาก หากเราต้องการให้รถบรรทุกของเราทำงานได้อย่างเต็มประสิทธิภาพ โดยเฉพาะในเรื่องของตัวกรองอากาศและตัวกรองเชื้อเพลิงที่สำคัญมาก ผู้เชี่ยวชาญส่วนใหญ่แนะนำให้เปลี่ยนตัวกรองอากาศทุกระยะทางประมาณ 15,000 ถึง 30,000 ไมล์ ขึ้นอยู่กับสภาพการขับขี่ ในขณะที่ตัวกรองเชื้อเพลิงโดยทั่วไปแล้วควรเปลี่ยนทุก 20,000 ถึง 30,000 ไมล์ ผู้ที่เป็นเจ้าของรถบรรทุกและปฏิบัติตามคำแนะนำของผู้ผลิตมักจะพบว่าชิ้นส่วนเหล่านี้ทำงานได้ดีกว่า เนื่องจากตรงตามความต้องการของยานพาหนะอย่างแม่นยำ การบันทึกประวัติการบำรุงรักษาผ่านระบบหรือเอกสารการบริการนั้นก็มีประโยชน์อย่างยิ่งเช่นกัน หากปราศจากการบันทึกที่เหมาะสม มักมีความเสี่ยงที่บุคคลอาจลืมว่าเปลี่ยนตัวกรองครั้งล่าสุดเมื่อไร ซึ่งอาจนำไปสู่ปัญหาร้ายแรงในระยะยาว เมื่อตัวกรองสกปรกเริ่มส่งผลต่อสมรรถนะโดยรวมของเครื่องยนต์

สัญญาณของไส้กรองน้ำมันหรือไส้กรองห้องโดยสารที่ตัน

การสังเกตว่าเมื่อไหร่ที่ตัวกรองเกิดการอุดตันช่วยป้องกันปัญหาใหญ่ที่อาจเกิดขึ้นในภายหลัง เมื่อเครื่องยนต์เริ่มทำงานแย่ลงกว่าปกติ หรือมีเสียงแปลกๆ มักจะหมายความว่ามีบางส่วนในระบบหล่อลื่นเกิดการอุดตัน โดยเฉพาะกับตัวกรองอากาศในห้องโดยสาร ผู้คนมักจะรู้สึกได้ว่าแรงดันลมที่ออกมาจากช่องแอร์ในรถยนต์ลดลง การตรวจสอบแรงดันน้ำมันอย่างสม่ำเสมอถือว่าสำคัญเช่นกัน เพราะหากแรงดันเริ่มมีความผิดปกติขึ้นลงแบบไม่แน่นอน อาจหมายความว่ามีปัญหาบางอย่างกับตัวกรองน้ำมันเอง ซึ่งอาจนำไปสู่การหล่อลื่นที่ไม่เพียงพอ และทำให้ชิ้นส่วนต่างๆ สึกหรอเร็วกว่าที่ควร ดังนั้นการสังเกตสัญญาณเตือนเหล่านี้แต่เนิ่นๆ จึงมีความสำคัญอย่างมาก เพื่อให้สามารถดำเนินการซ่อมบำรุงได้ก่อนที่ค่าใช้จ่ายในการซ่อมจะสูงลิ่ว

ปัจจัยทางสิ่งแวดล้อมที่ส่งผลต่ออายุการใช้งานของฟิลเตอร์

สภาพแวดล้อมมีผลอย่างมากต่ออายุการใช้งานของไส้กรองรถบรรทุกก่อนที่จะต้องเปลี่ยนใหม่ ไส้กรองที่ใช้บนถนน dusty หรือในพื้นที่ที่มีมลพิษสูง โดยเฉพาะในการขนส่งระยะทางไกล มักจะสกปรกเร็วกว่าปกติมาก ซึ่งหมายความว่าช่างเทคนิคจะต้องตรวจสอบบ่อยขึ้นและต้องเปลี่ยนไส้กรองเร็วขึ้นกว่าเดิม อีกทั้งสภาพอากาศที่หนาวจัดก็ส่งผลเสียต่อไส้กรองเช่นกัน ทำให้วัสดุสึกหรอเร็วขึ้น ในขณะที่สภาพอากาศร้อนอาจทำให้ชิ้นส่วนเกิดการบิดงอตามกาลเวลา ผู้ควบคุมรถบรรทุกควรมีนิสัยตรวจสอบไส้กรองอย่างสม่ำเสมอเมื่อต้องทำงานในสภาพแวดล้อมที่ยากลำบาก การทำเช่นนี้จะช่วยป้องกันการเกิดความล้มเหลวที่ไม่คาดคิด ซึ่งอาจส่งผลให้เครื่องยนต์เสียหาย และช่วยให้รถบรรทุกทำงานได้อย่างราบรื่นเป็นเวลานานระหว่างช่วงการบำรุงรักษาใหญ่

ผลกระทบที่เกิดจากการละเลยการบำรุงรักษาไส้กรองรถบรรทุก

ความเสี่ยงของการเสื่อมสภาพของเครื่องยนต์ก่อนเวลา

การไม่บำรุงรักษาไส้กรองของรถบรรทุกมักจะก่อให้เกิดปัญหาในระยะยาว โดยเริ่มต้นจากเครื่องยนต์เสื่อมสภาพเร็วขึ้น ไส้กรองอากาศที่ไม่ได้รับการตรวจสอบอย่างสม่ำเสมอจะมีแนวโน้มอุดตันตามกาลเวลา ทำให้มีสิ่งสกปรกและคราบสกปรกต่างๆ ไหลเข้าไปในห้องเครื่องยนต์ได้ สิ่งแปลกปลอมเหล่านี้จะก่อให้เกิดความเสียหายกับชิ้นส่วนภายในมากยิ่งขึ้น ซึ่งหมายความว่าช่างเทคนิคอาจต้องทำการซ่อมแซมที่มีค่าใช้จ่ายสูง หรือในกรณีที่เลวร้ายที่สุด อาจต้องเปลี่ยนเครื่องยนต์ใหม่ทั้งชุดในภายหลัง จากข้อมูลของอุตสาหกรรมพบว่า เครื่องยนต์มีอายุการใช้งานลดลงประมาณ 25 เปอร์เซ็นต์ เมื่อผู้ใช้งานละเลยการตรวจสอบไส้กรองตามกำหนด สรุปให้เข้าใจง่ายๆ คือ หากต้องการควบคุมค่าใช้จ่ายในการซ่อมแซมให้ต่ำ และต้องการให้รถบรรทุกทำงานได้อย่างราบรื่นตลอดหลายปีที่จะมาถึง ควรยึดมั่นตามช่วงเวลาในการบำรุงรักษาที่ผู้ผลิตแนะนำไว้

ต้นทุนการดำเนินงานที่เพิ่มขึ้นในระยะยาว

เมื่อผู้ใช้รถบรรทุกไม่สนใจการบำรุงรักษาไส้กรอง ก็จะต้องเสียเงินมากขึ้นในระยะยาว ไส้กรองที่สกปรกทำให้เครื่องยนต์ทำงานหนักขึ้น ซึ่งทำให้ใช้เชื้อเพลิงหมดไปเร็วกว่าที่ควร เราเคยเห็นผู้จัดการฝูงรถรายงานว่ามีค่าใช้จ่ายด้านเชื้อเพลิงเพิ่มขึ้นถึง 15% เฉพาะจากไส้กรองอากาศที่อุดตันเพียงอย่างเดียว และพูดตามจริงแล้ว เมื่อไส้กรองทำงานไม่ได้ตามปกติ ปัญหาทางกลก็จะเกิดขึ้นบ่อยครั้ง นั่นหมายความว่าต้องนำรถเข้าอู่บ่อยขึ้น และต้องเสียค่าซ่อมแซมที่สูงขึ้นตามมา ส่วนที่แย่ที่สุดคือ รถบรรทุกที่ไม่ได้เปลี่ยนไส้กรองเป็นประจำจะเสียมูลค่าไปมากเมื่อถึงเวลาที่ต้องขาย ไม่มีใครต้องการซื้อรถที่ถูกทอดทิ้งให้อยู่ในสภาพเช่นนี้ การตรวจสอบไส้กรองอย่างสม่ำเสมอไม่ใช่เพียงแค่ทำให้รถวิ่งได้อย่างราบรื่นเท่านั้น แต่ยังช่วยประหยัดค่าใช้จ่ายในแต่ละเดือน และรักษาไว้ซึ่งมูลค่าของรถที่ยังเหลืออยู่

การละเลยการบำรุงรักษาไส้กรองที่จำเป็นนั้นไม่ใช่แค่การลืมเพียงเล็กน้อยเท่านั้น แต่ยังส่งความเสี่ยงที่สำคัญต่อสมรรถนะของเครื่องยนต์และสุขภาพทางการเงินอีกด้วย การให้ความสำคัญกับการเปลี่ยนและบำรุงรักษาไส้กรองเป็นการลงทุนในความน่าเชื่อถือของรถบรรทุกในปัจจุบันและมูลค่าในการขายต่อในอนาคต

การเลือกฟิลเตอร์ที่เหมาะสมสำหรับรถบรรทุกของคุณ

การเลือกกรองที่เหมาะสมสำหรับรถบรรทุกของคุณนั้นมีความสำคัญต่อการรักษาสมรรถนะและความทนทานของรถ

การจับคู่ข้อมูลจำเพาะกับข้อกำหนดของยานพาหนะ

การรู้ว่าไส้กรองประเภทใดเหมาะกับรุ่นรถบรรทุกต่าง ๆ มีความสำคัญอย่างมากเมื่อพูดถึงการทำให้สิ่งต่าง ๆ ถูกต้องและมั่นใจว่าทุกอย่างทำงานได้อย่างราบรื่น ก่อนซื้อไส้กรองสำรอง ควรตรวจสอบข้อมูลจำเพาะและคำแนะนำของผู้ผลิตถือเป็นเรื่องสมเหตุสมผล การใช้ไส้กรองที่ผิดประเภทอาจก่อให้เกิดปัญหามากมายในระยะยาว ตั้งแต่สมรรถนะที่ลดลงจนถึงความเสียหายทางกลที่เกิดขึ้นจริง ไม่ต้องพูดถึงการสูญเสียการรับประกัน ยกตัวอย่างเช่น ไส้กรองอากาศ การใช้อะไรก็ตามที่ไม่พอดีจะทำให้อากาศที่มีฝุ่นเข้าไปในห้องเครื่องยนต์ ทำให้ชิ้นส่วนสึกหรอเร็วขึ้น และอาจนำไปสู่การเสียหายได้ หากปล่อยไว้โดยไม่แก้ไข

มาตรฐานคุณภาพสำหรับสภาพการขับขี่ที่รุนแรง

เมื่อเลือกตัวกรองสำหรับยานพาหนะที่ต้องเผชิญกับสภาพถนนที่ขรุขระ การเลือกตัวกรองที่ผ่านมาตรฐานคุณภาพที่เหมาะสมนั้นมีความสำคัญมาก หากเราต้องการให้ระบบทำงานได้อย่างเชื่อถือได้และมีประสิทธิภาพในระยะยาว ตัวกรองที่มีคุณภาพดีกว่านั้นจะทนทานต่อสภาพแวดล้อมที่หนักหน่วงและสกปรกได้ดีกว่า ซึ่งหมายความว่าพวกมันยังคงทำงานได้อย่างเหมาะสมแม้ในสถานการณ์ที่ถนนมีสภาพเลวร้าย มาตรฐานอุตสาหกรรม เช่น คะแนน ISO หรือเครื่องหมาย TS ไม่ใช่เพียงแค่การตลาดเท่านั้น แต่เป็นข้อมูลที่บ่งบอกอย่างชัดเจนว่าตัวกรองเหล่านี้มีคุณภาพการผลิตที่ดีเพียงใด ดังนั้นจึงสามารถใช้งานได้ในกรณีที่ตัวกรองธรรมดาล้มเหลว ลองนึกถึงรถบรรทุกขนาดใหญ่ที่ใช้เวลาส่วนใหญ่ในการวิ่งบนไซต์ก่อสร้างหรือถนนที่ฝุ่นเยอะ รถบรรทุกเหล่านี้ต้องการตัวกรองที่สามารถทำหน้าที่หลักสามอย่างได้ ได้แก่ มีประสิทธิภาพในการจับสิ่งปนเปื้อน ทนทานต่อการใช้งานซ้ำๆ ผ่านรอบของการสกปรกและการทำความสะอาด และที่สำคัญที่สุดคือปกป้องชิ้นส่วนเครื่องยนต์ที่ละเอียดอ่อนไม่ให้เสียหายจากสิ่งที่ถูกดูดเข้ามาทางระบบช่องดูดอากาศ