Types of Truck Filters and Their Core Functions

Truck Air Filters: Safeguarding Engine Health

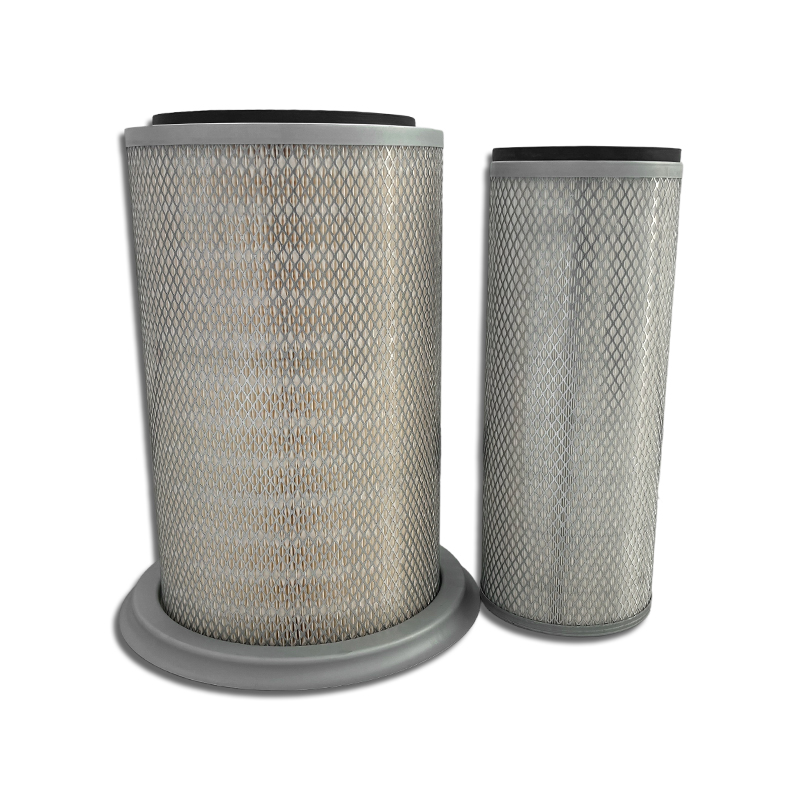

Air filters for trucks are really important for keeping engines healthy since they stop dirt and grime from getting inside where it doesn't belong. Without this protection, engines tend to wear out faster because all those tiny particles cause damage over time. Changing these filters regularly helps keep the air flowing properly through the engine, something that makes a big difference in how well the engine runs and lasts longer. Some research shows that when air filters stay clean, fuel efficiency can actually improve around 10 percent, so there's definitely value in maintaining them. Different trucks need different kinds of air filters too. What works great on one model might not be suitable for another, so checking what specifications are needed for each particular vehicle is pretty much mandatory if someone wants their truck running smoothly for years to come.

Truck Fuel Filters: Optimizing Combustion Efficiency

Fuel filters play a key role in keeping engines safe by removing dirt and debris from fuel before it gets into the combustion chamber. The process actually makes a big difference in how well the engine burns fuel and cuts down on bad emissions. The EPA reports that when fuel filters get dirty, they can really hurt engine performance and make emissions worse too. Keeping those filters clean matters a lot if someone wants their engine running smoothly. Also worth noting is that different trucks need different kinds of fuel filters depending on their model specs, so knowing what fits best helps maintain good performance over time. Regular checkups and replacements ensure everything works right in the fuel system, which means better gas mileage and longer life for the engine overall.

Oil Filters: Protecting Engine Lubrication Systems

Oil filters do the important job of pulling out dirt and debris from engine oil, something that keeps engines running smoothly and cuts down on unnecessary wear over time. When drivers stick to regular oil changes and replace filters when needed, they're actually doing their engines a big favor in terms of longevity. Some studies point to pretty shocking numbers too – dirty oil can lead to about 30% more wear on engine components compared to clean oil. That makes sense when we think about how metal parts rub against each other inside an engine. For truck owners specifically, getting good quality filters made for their particular model really matters. These specialized filters work better at keeping oil flowing properly through the system. Cleaner oil means less friction between moving parts, so the engine lasts longer and performs better overall. Most mechanics will tell anyone who asks that this simple maintenance step saves money in the long run by preventing major repairs down the road.

Cabin Air Filters: Enhancing Driver Comfort

Good cabin air filters make all the difference when it comes to clean air inside trucks. They pull out stuff like pollen, dust, and other nasties that float around while driving. For those drivers hitting the road day after day, this means breathing easier during those long hauls across country. Most mechanics suggest swapping out these filters somewhere between 12k and 15k miles just to keep them working properly. Nobody wants to deal with stale air or weird smells floating through the cab. A decent filter does more than just catch bad stuff too it actually helps the heating and cooling system run better, so the whole cabin stays nicer for everyone involved. Drivers who aren't choking on dirty air tend to be happier people overall, and happy drivers get things done faster.

How Truck Filters Directly Impact Vehicle Performance

Engine Longevity and Reduced Wear

When truck filters work properly, it means less engine wear and trucks that stay on the road for years instead of breaking down early. Studies from mechanics and fleet operators back this up time after time showing that sticking to maintenance plans cuts down on breakdowns. The main thing here? Changing those filters regularly. Fresh filters let oil flow better through the engine and help keep things cool when the engine gets hot under load. Most drivers know this already but still skip it because it's easy to forget. However, keeping up with filter replacements makes a huge difference in how long engines actually last before needing major repairs or replacement parts.

Fuel Efficiency and Emissions Control

Keeping truck filters properly maintained makes a real difference in how well fuel burns and cuts down on overall fuel usage. According to the EPA, clean air filters help meet those tough emission standards because clogged filters just let out more pollutants than they should. When fleets invest in good quality replacement filters, their trucks actually produce fewer greenhouse gases, which is obviously better for the environment. The savings at the pump are nice too, but there's another angle here worth mentioning. Cleaner burning engines mean less soot buildup inside the system, something mechanics know all too well from experience. For companies running large diesel fleets, regular filter changes aren't just about compliance anymore they've become part of everyday business strategy for staying green while keeping operational costs under control.

Maintenance Schedules and Replacement Indicators

Recommended Intervals for Air and Fuel Filters

Sticking to industry standards matters a lot if we want our trucks performing at their best, particularly regarding those all important air and fuel filters. Most experts suggest changing air filters somewhere between 15k and 30k miles depending on driving conditions, whereas fuel filters generally need replacing around the 20k to 30k mark. Truck owners who follow what the manufacturer recommends usually find that these parts work better because they match exactly what the vehicle needs. Keeping track of maintenance history through some sort of service record proves incredibly helpful too. Without proper records, there's always a risk someone might forget when filters were last changed, which can lead to serious problems down the road as dirty filters start affecting how well the engine runs overall.

Signs of a Clogged Oil or Cabin Filter

Spotting when a filter gets clogged helps avoid major problems later on. When engines start performing worse than usual or making strange sounds, that usually means there's some kind of blockage in the oil system somewhere. With cabin air filters specifically, people tend to notice less airflow coming through the vents inside their cars. Checking oil pressure regularly matters too because if it starts going up and down unpredictably, something might be wrong with the oil filter itself. This could lead to poor lubrication which wears out parts faster than normal. Catching these warning signals early makes all the difference for getting maintenance done before things get really expensive to fix.

Environmental Factors Affecting Filter Lifespan

The environment has a big effect on how long truck filters last before needing replacement. Filters used on dusty roads or in areas with high pollution levels, especially common on some long distance hauls, tend to get dirty much faster than normal. This means mechanics have to check them more often and replace them sooner rather than later. Cold weather can also be tough on filters, causing materials to break down quicker while hot climates might warp components over time. Truck operators should make it a habit to inspect filters regularly when working in harsh conditions. Doing so helps prevent unexpected failures that could damage engines and keep vehicles running smoothly for longer periods between major maintenance sessions.

Consequences of Neglecting Truck Filter Maintenance

Premature Engine Degradation Risks

Failing to maintain truck filters will almost certainly cause problems down the road, beginning with faster engine breakdowns. Air filters that aren't regularly checked tend to get clogged up over time, letting all sorts of dirt and grime slip into the engine compartment where they don't belong. These unwanted particles create extra wear on internal components, which means mechanics might end up doing expensive repairs or worse case scenario complete engine replacement later on. Industry data suggests engines last roughly 25 percent less when owners skip regular filter checks. The bottom line? Stick to those manufacturer suggested service intervals if wanting to keep repair bills low and ensure the truck keeps running smoothly for years ahead.

Increased Operational Costs Over Time

When truck owners ignore filter maintenance, they end up paying way more in the long run. Dirty filters make engines work harder, which burns through fuel faster than it should. We've seen some fleet managers report up to 15% extra fuel costs just from clogged air filters alone. And let's face it, when filters aren't doing their job properly, mechanical problems pop up all the time. That means more trips to the shop and bigger repair bills down the road. The worst part? A truck that hasn't had regular filter changes loses serious value when it comes time to sell. Nobody wants to buy a rig that's been neglected like this. Regular filter checks aren't just about keeping things running smoothly either. They actually save money month after month while protecting what remains of the vehicle's worth.

Neglecting essential filter maintenance is more than just a minor oversightâit poses substantial risks to engine performance and financial health. Prioritizing filter replacement and maintenance is an investment in both the truck's present reliability and future resale value.

Selecting the Right Filters for Your Truck

Choosing the correct filters for your truck is crucial to maintaining its performance and longevity.

Matching Specifications to Vehicle Requirements

Knowing what kind of filters work best with various truck models matters a lot when it comes to getting things right and making sure everything runs smoothly. Before buying replacement filters, checking what the manufacturer says about their specs and recommendations makes sense. Wrong filters might cause all sorts of problems down the road, from reduced performance to actual mechanical damage, not to mention possibly wiping out warranty coverage. Take air filters as an example. Putting in something that doesn't fit properly lets dirty air get into the engine compartment, which wears down components faster and eventually leads to breakdowns if left unchecked.

Quality Standards for Harsh Driving Conditions

When picking out filters for vehicles that face rough road conditions, going for ones that actually meet proper quality standards really matters if we want reliable operation and good long term performance. Better quality filters just hold up much longer under all that stress and dirt, which means they keep working properly even when things get tough on the road. Those industry certifications like ISO ratings or TS marks aren't just marketing fluff either they actually tell us something concrete about how well made these filters truly are, so they work where regular filters would fail. Think about big rigs that spend most of their time bouncing around construction sites or dusty back roads. These trucks need filters that do three main things stay efficient at trapping debris, last through countless cycles of dirt and cleaning, and most importantly protect sensitive engine parts from getting damaged by whatever gets sucked in through the air intake system.