How Truck Filters Support Engine Efficiency and Longevity

Truck filters are essential for maintaining engine performance and extending operational life by controlling contamination in three core systems: air, oil, and fuel. Proper filtration ensures efficient combustion, clean lubrication, and reliable fuel delivery—each critical to minimizing wear and maximizing uptime.

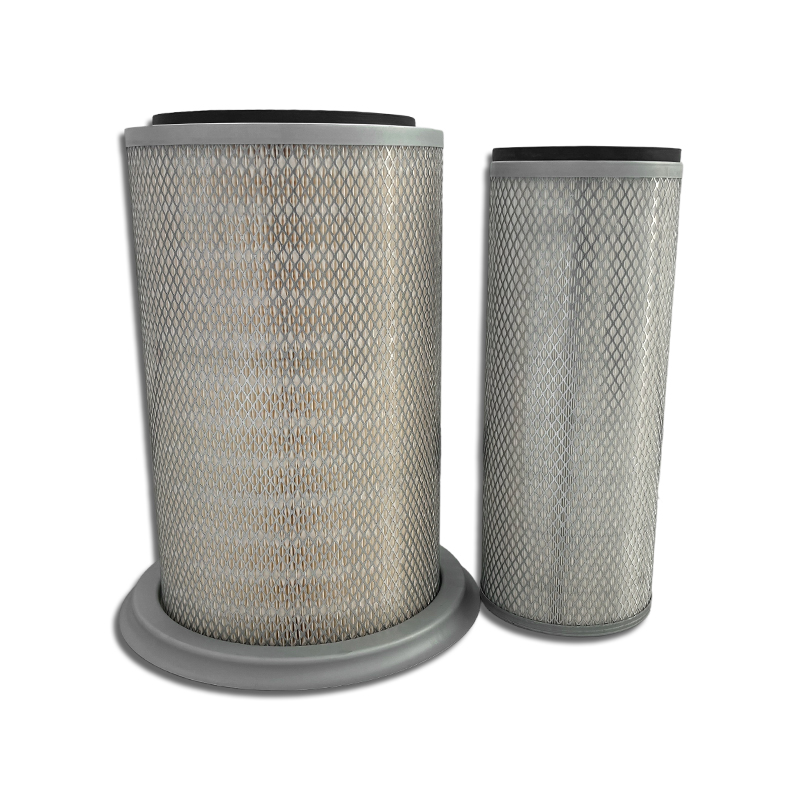

The Role of Air Filters in Fuel Combustion and Engine Efficiency

Good air filters let the right amount of oxygen get into the engine for proper combustion, which makes a big difference in how efficiently fuel burns. According to a recent study by SAE from 2023, engines running with clean air filters actually burn fuel 12 to 15 percent more efficiently compared to when the filters are dirty and blocked up. When there's steady airflow coming in, the engine can keep the perfect balance between air and fuel, so less fuel goes wasted and carbon doesn't build up as much inside. The best filters out there, ones that meet ISO 5011 standards, trap more than 98% of all the tiny particles floating around in the air. These filters stop gritty stuff from getting into the engine where it would wear down piston rings faster. And we know this matters because Commercial Fleet Analytics reported back in 2022 that worn out piston rings caused problems in about one out of every four early engine failures among heavy duty trucks.

How Oil Filters Maintain Clean Lubrication and Protect Critical Engine Components

Oil filters catch all sorts of nasty stuff down to around 10 microns in size. We're talking about things like tiny metal bits and carbon sludge buildup which actually cause about 80% of the wear on bearings and camshafts inside diesel engines. The newer models using synthetic filter media are pretty impressive too. They trap at least 94 percent of contaminants according to Fluid Analysis Quarterly from last year, and many mechanics report being able to stretch out oil changes by anywhere between three thousand to five thousand miles while still keeping the engine protected. When we look at why engines fail catastrophically, lubrication problems come in at number two behind only mechanical failure, making up roughly 34% of major breakdowns according to NTSB reports on commercial vehicle incidents. So good filtration isn't just nice to have it's absolutely essential for maintaining reliable engine performance over time.

Fuel Filter Function in Preventing Contamination in Diesel-Powered Truck Engines

Diesel fuel tends to get contaminated pretty easily from things like water getting mixed in, microbes growing inside, and tiny particles floating around. These problems really mess with those high pressure injectors that work at over 30 thousand pounds per square inch. The newer fuel filters on the market actually comply with ISO 16332 standards these days. They take out almost all (like 99.9%) of those pesky 2 micron particles and separate away about 95% of the water content too. According to a recent 2024 survey looking at fleet maintenance records, trucks equipped with these nano fiber filters saw their injector replacement rates drop by nearly half (around 47%) and had 19% fewer cases where fuel washed out completely compared to older models still using regular cellulose filters. Beyond saving money on parts, this kind of protection also prevents expensive damage to those high pressure fuel pumps we're talking about here something that can run upwards of twelve grand for repairs.

Air Filters: Maximizing Combustion Efficiency and Fuel Economy

Benefits of High-Quality Air Filters for Engine Performance and Fuel Efficiency

High quality air filters employ several layers of synthetic material that captures around 99.6 percent of particles bigger than 5 microns, which helps keep the air flowing properly through the engine while also promoting good combustion. Cars with upgraded filter systems tend to get between 4 and 7 percent better gas mileage, plus their turbochargers last about 15 percent longer before needing replacement. Clean intake systems matter because dirty air can really hurt performance over time. These filters cut down on harmful emissions too, so engines stay responsive when drivers need them most, whether accelerating on the highway or climbing hills.

Impact of Clogged Air Filters on Power Output and Fuel Consumption

When air filters get clogged, engines have to push much harder just to maintain speed on highways. Research published in the Heavy Duty Vehicle Systems Journal back in 2023 found that restricted airflow makes engines work around 23% harder overall. This extra strain actually cuts down on horsepower by nearly 18% while making fuel consumption jump between 9 and 12%. The problem gets worse because the engine ends up running richer mixtures, which means soot builds up faster inside those expensive diesel particulate filters. And it's not just about performance either. Fleet managers report seeing DEF fluid consumption go up by roughly 40% whenever intake airflow falls under 700 cubic feet per minute. These numbers really add up over time for commercial operations managing large vehicle fleets.

Signs of Failing Air Filters in Semi-Truck Engines

Common indicators of air filter failure include:

- 12–15% RPM fluctuation at idle

- Black exhaust smoke during acceleration

- Intake manifold pressure deviations exceeding 5 PSI

- Reduced regenerative braking efficiency in hybrid diesel models

These symptoms signal airflow restrictions that compromise performance and emissions control.

OEM vs. Aftermarket Air Filters: Performance and Reliability in Heavy-Duty Applications

OEM air filters demonstrate 28% greater dust-holding capacity under ISO 5011 testing and maintain efficiency longer than aftermarket counterparts, which show 19% faster performance decay after 15,000 miles. While 63% of aftermarket filters meet minimum SAE J726 standards, 91% of OEM designs incorporate proprietary nanofiber coatings that enhance durability and extend service intervals.

Oil and Fuel Filters: Protecting Engine Systems from Contamination

Critical Role of Oil Filters in Sustaining Engine Health and Lubrication Efficiency

Oil filters trap particles down to around 20 microns which is roughly 1/5th the thickness of a single strand of human hair. This helps maintain proper oil consistency while safeguarding important parts such as crankshaft bearings and timing chains according to research from the 2023 Heavy Duty Engine Study. Trucking companies that switch to synthetic media oil filters see about 38 percent fewer early engine overhauls than fleets still relying on old fashioned cellulose filters per data collected in the 2024 Fleet Maintenance Report. The numbers clearly show why many operators are making this change for better engine longevity.

Oil Filter Replacement Schedules Based on Operating Conditions and Fleet Usage

Standard 15,000-mile replacement intervals should be adjusted based on operating severity:

- Extreme loads: Reduce interval by 25% for dump trucks and haulers

- Dusty environments: Shorten cycles by 40% in mining or construction

- Low-mileage fleets: Replace annually to prevent additive degradation

Telematics data from 12,000 Class 8 trucks indicates that engine load cycles are a more accurate predictor of optimal filter life than mileage alone.

How Fuel Filters Prevent Water and Debris Contamination in Diesel Engine Systems

Modern 4-micron fuel filters capture 99.8% of particulates and separate 95% of water using coalescing media. This dual protection prevents two major failure modes:

- Corrosive wear from microbial growth and electrolytic damage

- Injector damage due to particulate contamination in high-pressure common rail systems

A 2023 analysis of 5.6 million service records found a 62% reduction in fuel system repairs after fleets upgraded to nano-fiber filters.

Case Study: Consequences of Fuel Filter Failure in Long-Haul Trucking Fleets

A Midwest logistics company suffered 12 engine failures within eight months—totaling $740,000 in repairs—due to extended filter service intervals. Post-failure inspections revealed:

- 83% of failed injectors contained sub-10-micron silica particles

- Water contamination exceeded OEM limits by six times in nine cases

- Average downtime per incident: 14.7 days

After adopting predictive monitoring and mandatory 10,000-mile filter replacements, fuel system failures dropped by 91% over two years (2024 Fleet Optimization Report).

Proactive Maintenance Strategies for Optimal Truck Filter Performance

Best Practices for Truck Filter Inspection and Replacement in Fleet Operations

Regular maintenance prevents 72% of avoidable engine failures (2023 maintenance data). Conduct biweekly air filter inspections in dry climates and monthly checks in moderate conditions. Use compressed air for light cleaning, but replace filters with permanent pleat deformation or oil saturation to ensure continued protection.

Customizing Filter Service Intervals Based on Driving Conditions and Load Cycles

| Operating Condition | Air Filter Replacement | Fuel Filter Replacement |

|---|---|---|

| Urban Delivery (Stop-and-go) | 15,000–20,000 miles | 10,000–12,000 miles |

| Long-Haul Highway | 25,000–30,000 miles | 15,000–18,000 miles |

| Off-Road/Construction | 5,000–8,000 miles | 8,000–10,000 miles |

Adjust intervals by 20%–40% in extreme temperatures or high-particulate environments to maintain system integrity.

Following Manufacturer Guidelines for Truck Filter Maintenance Schedules

Adhering to OEM specifications satisfies 89% of engine warranty requirements. Deviations can increase repair costs by an average of $3,200 per incident (Commercial Fleet Data 2024). Always verify replacement filter part numbers against original equipment specifications to ensure compatibility and performance.

Reducing Engine Downtime Through Regular Filter Performance Monitoring

Integrate real-time pressure differential monitoring to detect air filter restrictions exceeding 25 inH—O. Address water-in-fuel alerts immediately, as delayed service risks injector damage costing over $8,500. Predictive maintenance technologies have been shown to reduce unplanned filter-related downtime by 61% in fleet trials, making them a key tool for maximizing operational efficiency.

FAQ

What are the signs my truck's air filter needs replacing?

Signs include RPM fluctuations at idle, black smoke during acceleration, intake pressure deviations, and lower braking efficiency.

How often should I replace oil and fuel filters in my fleet?

Oil filters in extreme loads should be reduced by 25%, and 40% in dusty environments. Fuel filters should be checked at 10,000 miles, and adjusted based on specific conditions.

Table of Contents

- How Truck Filters Support Engine Efficiency and Longevity

- Air Filters: Maximizing Combustion Efficiency and Fuel Economy

-

Oil and Fuel Filters: Protecting Engine Systems from Contamination

- Critical Role of Oil Filters in Sustaining Engine Health and Lubrication Efficiency

- Oil Filter Replacement Schedules Based on Operating Conditions and Fleet Usage

- How Fuel Filters Prevent Water and Debris Contamination in Diesel Engine Systems

- Case Study: Consequences of Fuel Filter Failure in Long-Haul Trucking Fleets

-

Proactive Maintenance Strategies for Optimal Truck Filter Performance

- Best Practices for Truck Filter Inspection and Replacement in Fleet Operations

- Customizing Filter Service Intervals Based on Driving Conditions and Load Cycles

- Following Manufacturer Guidelines for Truck Filter Maintenance Schedules

- Reducing Engine Downtime Through Regular Filter Performance Monitoring

- FAQ