The Critical Role of Assembly Housing in Automotive Integration

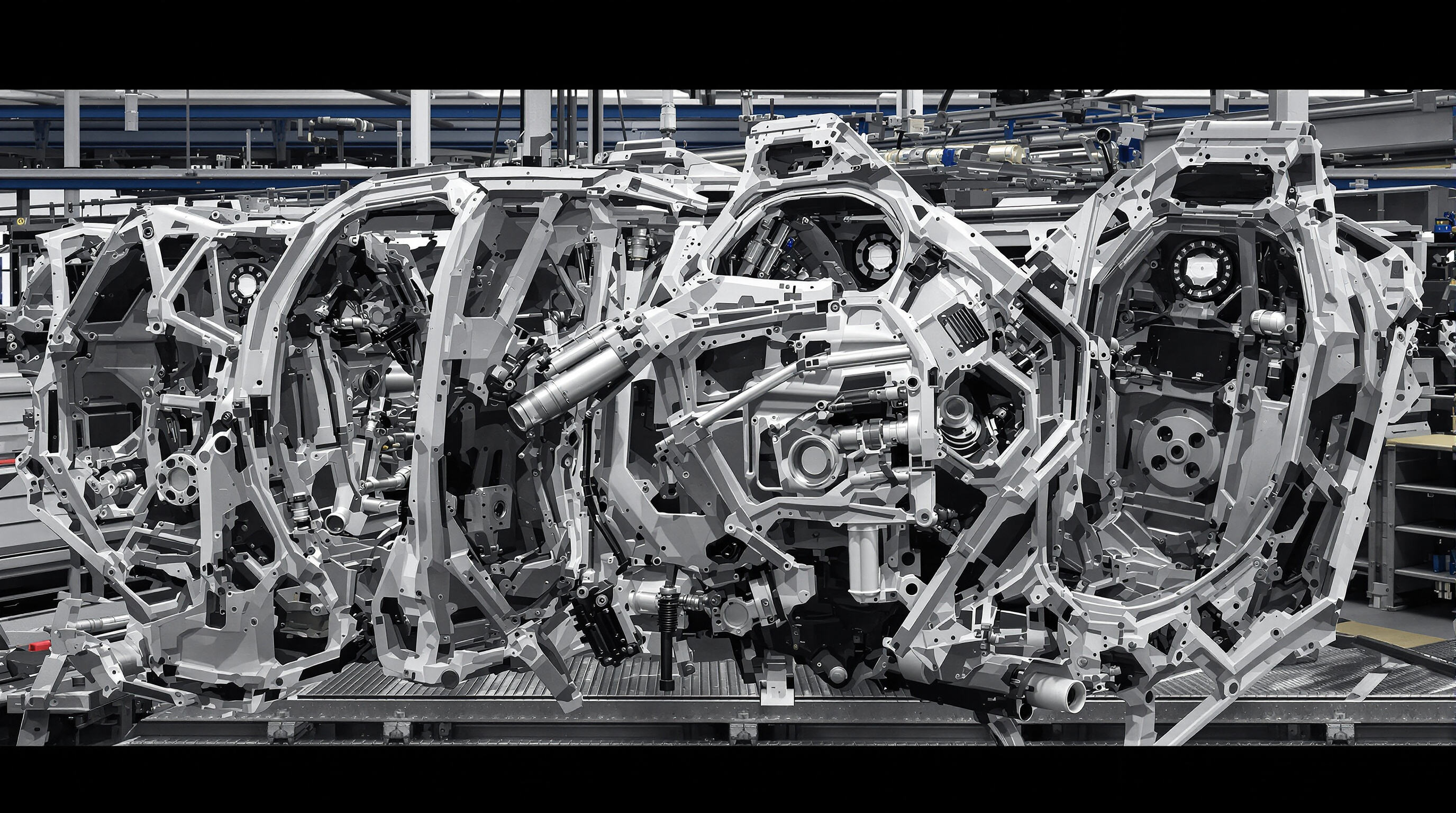

How Assembly Housing Supports Integration of Complex Auto Parts

The modern assembly housing acts as the backbone when it comes to putting together those high tech automotive systems we see today, including things like ADAS sensors and electric vehicle battery modules. When manufacturers combine all these parts into one single housing unit, they actually cut down on complicated wiring setups while getting better alignment precision. And this matters a lot for technologies that need exact measurements down to the millimeter, think LiDAR systems for instance. A recent look at data from SAE International back in 2024 showed some pretty impressive results too. Their research found that these integrated housing designs helped spread out the weight of EV batteries more evenly across vehicles, which is about a 22% improvement over traditional methods. Plus there was an 18% boost in how well the cars protected against crashes during testing scenarios compared to older mounting approaches where everything was separate.

Design for Assembly (DFA) Principles in Automotive Manufacturing

Leading manufacturers apply Design for Assembly (DFA) principles through three key housing features:

- Unified fastening patterns enabling robotic installation of 12+ subsystems simultaneously

- Standardized connector layouts that cut wiring errors by 43% (SAE 2023 Assembly Efficiency Report)

- Integrated alignment features supporting collaborative robotics workflows

These design strategies reduced assembly defects by 31% in high-volume EV production lines, as shown in 2023 manufacturing data.

Minimizing Part Count Through Integrated Housing Design

Progressive automakers have reduced part counts by 40–60% by combining traditionally separate functions into single housing units. Multi-functional designs now embed structural load paths, thermal management channels, EMI shielding, and vibration dampening systems. This consolidation enables leading EV manufacturers to achieve 30% faster production cycles compared to traditional component stacking methods.

Case Study: Reducing Assembly Time by 30% With Optimized Housing

A 2024 production trial demonstrated that a redesigned motor controller housing eliminated 127 fasteners and 18 discrete components through:

- Snap-fit architecture replacing threaded connections

- Integrated coolant routing eliminating separate hoses

- A unified connector panel standardizing 32 electrical interfaces

This redesign enabled modular assembly workflows, reducing station time from 8.7 to 6.1 minutes per unit while maintaining a 99.96% first-pass quality rate.

Modular Design and Sub-Assemblies: Building Flexibility into Assembly Housing

Modular Subassemblies and Reusable Components in Automotive Systems

Car makers today are moving toward modular assembly housing designs, which has helped slash production complexity somewhere around 18 to 22 percent according to McKinsey from last year. The new approach relies on standard parts like already wired sensor groups and fuel injection brackets that work across different car models. A big name European manufacturer actually showed how these repeatable housing bits shaved off nearly a third of their development timeline without losing the ability to tailor vehicles for local markets across Europe.

Integration of Functional Features Into Housings for Modularity

Advanced assembly housings now incorporate structural mounting points, alignment guides, and thermal management channels directly into their core architecture. As a 2024 Society of Automotive Engineers benchmark study found, this approach eliminates 6–8 auxiliary components per module compared to traditional designs, enabling maintenance teams to swap entire subsystems in under 15 minutes.

Trend: Plug-and-Play Modules Enabled by Smart Assembly Housing Design

Forty-seven percent of Tier 1 suppliers now use housings with self-aligning connectors and tool-less fastening systems, contributing to a 30% reduction in final assembly errors (Deloitte Automotive Report 2023). These intelligent designs support robotic installation of pre-validated modules—including engines, infotainment systems, and braking components—equipped with built-in quality verification features.

Applying DFMA to Reduce Cost and Complexity in Assembly Housing

Modern automotive manufacturers achieve 18% waste reduction in material costs (Ponemon Institute 2023) by implementing Design for Manufacturing and Assembly (DFMA) principles. This methodology systematically optimizes housing designs to eliminate unnecessary complexity while meeting functional requirements.

Applying DFMA to Streamline Manufacturing and Assembly Processes

DFMA principles drive 23% faster production cycles by focusing on three critical areas:

- Component Consolidation: Replacing 8–12 discrete fasteners with unified snap-fit geometries

- Process Optimization: Incorporating self-locating features that reduce robotic alignment time by 40%

- Error-Proofing: Using color-coded mating surfaces to reduce assembly mistakes by 67%

Standardization of Components and Fasteners Within Housing Units

Leading manufacturers achieve 30% cost savings through strategic standardization of:

| Standardized Element | Cost Impact | Example Implementation |

|---|---|---|

| Fastener Types | 22% reduction | M4 hex screws across 85% of housing joints |

| Interface Dimensions | 17% efficiency gain | Unified 25mm mounting grid pattern |

| Material Specifications | 14% waste reduction | Single-grade aluminum alloy for all non-load-bearing surfaces |

This approach aligns with industry guidelines for standardizing components while preserving design flexibility.

Balancing Customization and Standardization in High-Volume Production

Automakers resolve the mass-production paradox through:

- Modular Architecture: 70% standardized base housing with 30% configurable add-ons

- Post-Process Customization: Laser-etching identification markers on completed assemblies

- Family-Mold Tooling: Single die casting that produces 4–6 housing variants simultaneously

This balanced strategy has reduced changeover time by 38% while maintaining 92% compliance with customer-specific feature requirements.

Optimizing Assembly Motion and Part Handling Through Housing Design

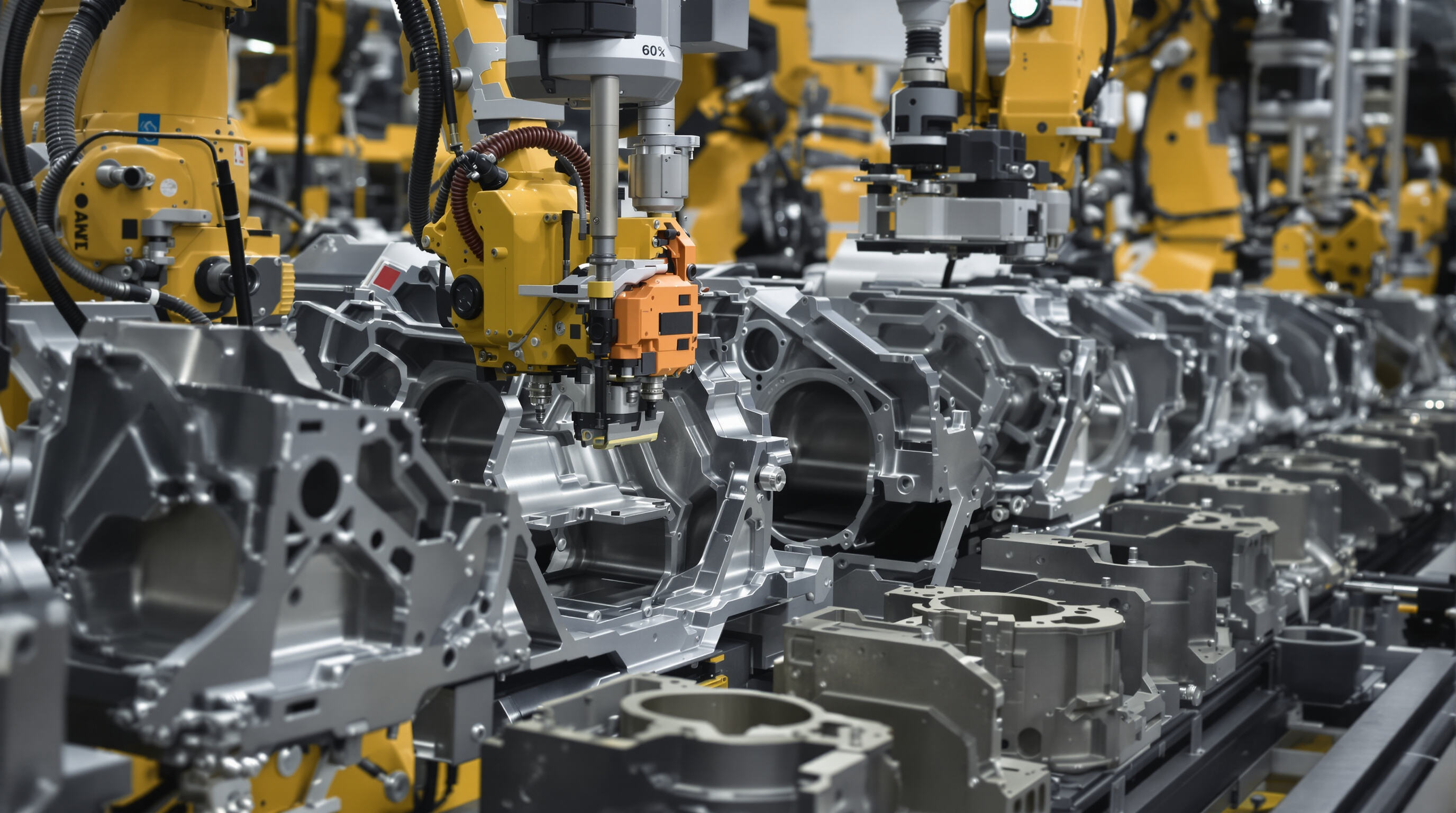

Part orientation and handling challenges in automated assembly

Modern automotive assembly lines require robots to position components with ±0.1 mm precision. With 23% of assembly delays attributed to part reorientation needs (Automotive Manufacturing Quarterly 2023), strategic housing design plays a critical role in mitigating inefficiencies. Key solutions include:

- Asymmetric alignment features preventing inverted installation

- Integrated lead-in chamfers guiding connectors and bolts

- Color-coded interfaces for mixed-material systems

Top-down assembly strategies enabled by intelligent housing architecture

Leading manufacturers are shifting to vertical integration, where 86% of components install via single-axis motion. This approach reduces:

- Tool changeovers by 40%

- Simultaneous operator actions by 55%

- Component flipping requirements by 72%

Housings with graduated snap-fit tiers and magnetic alignment guides enable true z-axis assembly—particularly advantageous for EV battery modules and ADAS sensor clusters.

Motion analysis in robotic assembly and its impact on housing design

Advanced motion-tracking systems reveal that 34% of robotic path adjustments stem from housing geometry conflicts. Next-generation designs address these issues through:

| Optimization Factor | Implementation | Cycle Time Reduction |

|---|---|---|

| Tool clearance | Angled service ports | 12% |

| Grip access | Flared edges | 8% |

| Vision system LOS | Reflective markers | 15% |

This data-driven refinement transforms housings from passive enclosures into active enablers of efficient assembly.

Material and Structural Innovations Enhancing Assembly Housing Performance

Today's housing designs for assemblies make use of cutting edge materials and clever construction methods to keep up with what manufacturers need these days. Take carbon fiber reinforced plastics (CFRP) and those aluminum magnesium blends for instance they cut down on weight by about 40 percent when compared to regular steel, yet still hold their shape and strength. The lighter weight means better fuel economy overall, plus these materials don't rust away like older ones did. Research indicates that parts made with CFRP last around 15 to 20 percent longer in places where there's constant shaking and movement, which is huge for machines that run nonstop.

Lightweight Materials Improving Efficiency and Durability

Automakers prioritize material innovation to balance strength and weight. Aluminum die-cast housings with internal ribbing achieve 25% higher torsional stiffness than conventional designs, allowing for slimmer profiles while maintaining crash safety. Hybrid polymer-metal housings further reduce thermal expansion mismatch in EV battery modules, minimizing seal degradation over time.

Component Aggregation and Part Simplification for Robust Design

Many manufacturers are now combining around 10 to 15 separate parts into one housing unit thanks to advances in 3D printing technology. Recent studies from the industry sector show something interesting happening too. When companies start putting sensors and connectors directly into these structural housings during production, they actually see about a third fewer mistakes when assembling transmission systems. The benefits don't stop there either. These integrated designs typically need 60% fewer bolts and screws overall. Plus, they handle tolerances better and last longer in real world conditions. What's really impressive is how these multi-purpose housings stand up to vibration. Tests indicate they can soak up two to three times more shock compared to old fashioned bolt together assemblies that have been used for decades.

FAQs

What is assembly housing's role in automotive integration?

Assembly housing integrates complex automotive parts, improving alignment precision and reducing wiring setups, which is crucial for technologies like LiDAR systems.

How do Design for Assembly (DFA) principles enhance automotive manufacturing?

DFA principles include unified fastening patterns, standardized connector layouts, and integrated alignment features, reducing assembly defects and enabling efficient robotic installation.

What innovations are improving assembly housing designs?

Innovations include lightweight materials like CFRP, advanced 3D printing for part simplification, and smart designs enabling plug-and-play modules and efficient assembly workflows.

Table of Contents

- The Critical Role of Assembly Housing in Automotive Integration

- Modular Design and Sub-Assemblies: Building Flexibility into Assembly Housing

- Applying DFMA to Reduce Cost and Complexity in Assembly Housing

- Optimizing Assembly Motion and Part Handling Through Housing Design

- Material and Structural Innovations Enhancing Assembly Housing Performance

- FAQs